01 Design

TOPWELL PRODUCTS

Topwell Glass Essential Oil Diffuser

Ultrasonic Aromatherapy 120ml Diffuser With 7 Color LED Lights Adjustable Mist Mode Auto Shut-off for Home office Baby

Water heated mattress

The water heated mattress is composed of a host, a mattress and a remote control.Products are manufactured from high quality materials.Separation of water and electricity.There is no power supply in the mattress, so it is safe and reliable.Achieve intelligent temperature control, freely adjust the temperature suitable for your own And no radiation, no drying, health treatment, no fire, ultra quiet .Give you a warm, comfortable and healthy smart sleep experience

White Noise Machine

6 Unique Non-Looping Natural and Soothing Sounds for Sleeping & Relaxation, High Fidelity Sleep Sound Machine with Sleep Timer

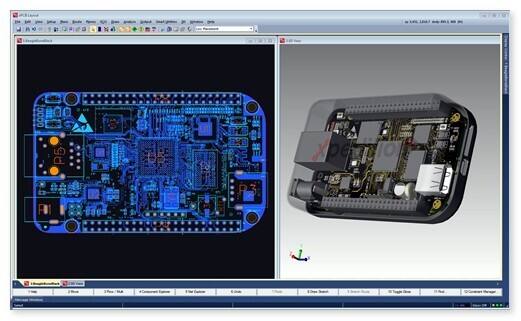

ELECTRONIC DESIGN

Architecture Design

Structural Design provides the ability to anticipate possible outcomes of the Design and take the suitable decisions to prevent faults. A wide range of Design and analysis activities are carried out including Concept Sketching, 2D Design & Drafting, 3D Modelling, Prototyping. Performance, Safety , tolerance and thickness analyses are also carried out . The prototypes and 3D models are examined using the best of line analytical tools to find out how they fail and glitches are fixed improving the overall performance.

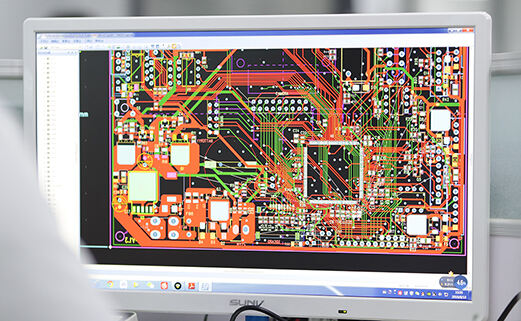

Multi Layer PCB Design

Utilizing suitable tools and latest equipments and techniques, our highly experienced professionals cover all aspects of PCB engineering to provide our clients with physical layout that matches exactly with the schematic design. Multilevel checks besides design reviews assure the quality of the final layout. Furthermore Topwell also has proficiency in high-performance Multilayer printed circuit boards which are needed to run very high speed signals on multiple layers.

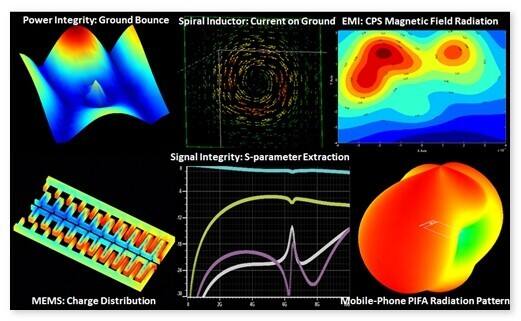

PI/SI Analysis

At this stage a detailed Design documents are developed containing drawings and other manufacturing information. All this activity is carried out much before the design is completed. This contains information such as Design specifications, Technical requirements for all design-related information required for manufacturing the fully defined complete product.

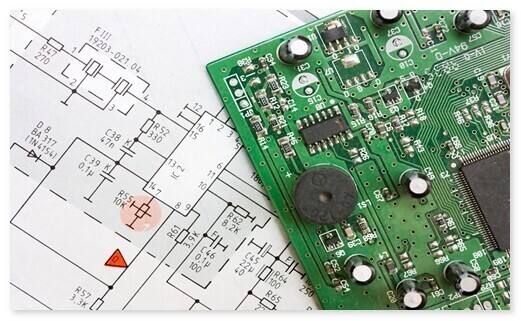

Schematics Design

TopWell is specialized in providing effective PCB services to be utilized in the product assembly. Our team design robust circuits using the best practices and methodologies. We design almost all types of electronic circuits and products according to custom specifications at affordable costs, while maintaining the highest possible quality. Topwell has expertise in designing high-performance PCB physical design. We have the mastery in providing end to end solutions which includes the full design flow in board development cycle from schematic capture to Board fabrication. Briefly, Topwell is the one stop station for the entire PCB Engineering requirements.

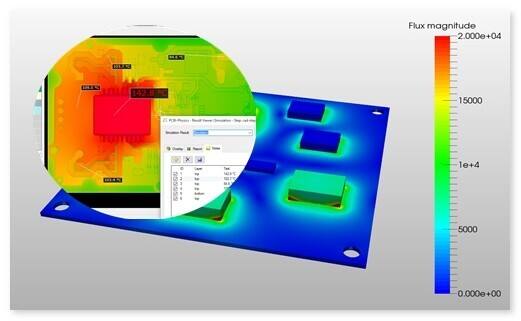

Thermal Analysis

Topwell holds a reputation of being one of the leading providers of Electro-Mechanical product design services in china. Electro-Mechanical Modelling is carried out to model and simulate an electro-mechanical system and thus its physical parameters can be examined before the actual system is built. The model is revised and enhanced till all decided conditions are met. This helps the client to develop flawless and accurate product at affordable prices, with shortest possible design lead time.

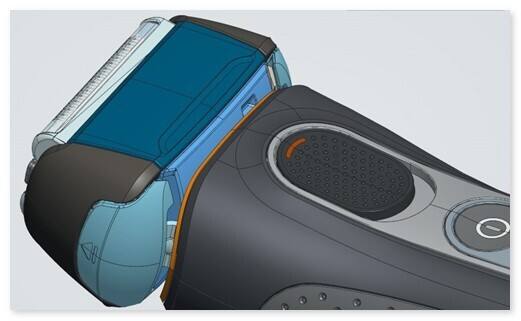

INDUSTRIAL DESIGN

CMF Design

CMF is that zone of design which deals with colour, materials, and finishing which gives the most appropriate colour scheme, materials, texture. We pay attention to the Rules of colour harmony and Modelling features as the colour schemes should be in line with the modelling features. We also take into consideration the Features of a specific process as colours can have different effects if created by different processes.

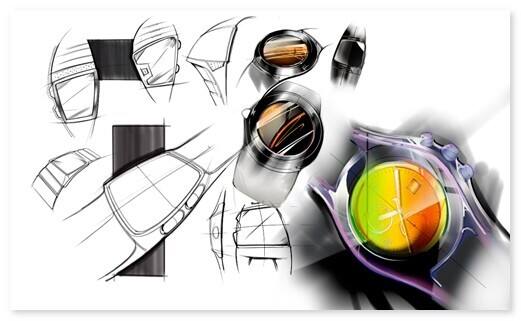

Concept

A concept is a hand-drawn or digital sketch which externalizes the designer’s ideas and thoughts in simple line-work to communicate the Design direction. During The development process any new ideas developed are incorporated in it. These concepts undergo refining stages, and are illustrated into 3D ideas and rendered presentations. Thus the client can comprehend design direction at early stage of product development. As an outcome of constant client involvement the results are synchronized with the product requirements.

Context Visualization

This involves visualisation of the product in user’s context. We evaluate the design by visualizing in context. Design options are evaluated with real –time interactional visualisation of the product.

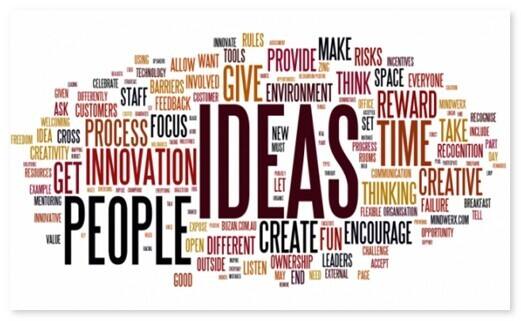

Research

Design research is a primary process of product design. Our Industrial Design department has integrated the Design research in the process of designing and it aims to understand and improve the design processes and practices quite widely, rather than developing domain-specific knowledge within any professional field of design.

Research Design

research is a primary process of product design. Our Industrial Design department has integrated the Design research in the process of designing and it aims to understand and improve the design processes and practices quite widely, rather than developing domain-specific knowledge within any professional field of design.

Validation

It is an exploratory process which affirms that the product functions as per the specifications of customer. It reduces development risk and time effectively during the development of the product. The device is tested under simulated use. Validation controls activity that happens later in the development process of the product.

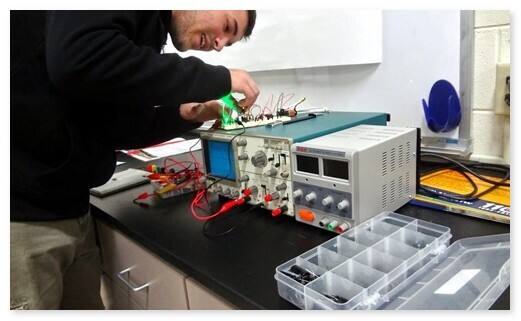

Working Prototyping

Eventually we arrive at the final product of the entire prototyping process which is the Working Prototype resembling and functioning similar to a finished product. At this stage the client has a Prototype at his disposal for testing. The performance of various materials and the functionality of the design is tested and refined.

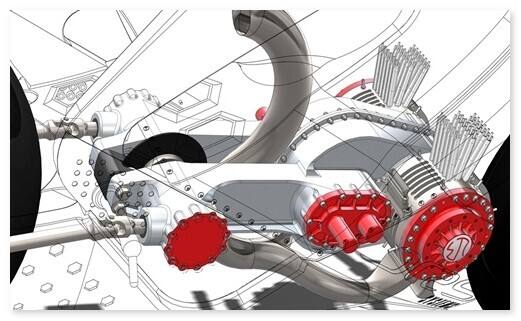

MECHANICAL DESIGN

2D Drawing and Specification Documents

At this stage a detailed Design documentation is made containing drawings and other manufacturing information. All this activity is carried out much before the design is completed. This contains documents such as Design specifications, Technical requirements and all the design-related information required for manufacturing the fully defined complete product.

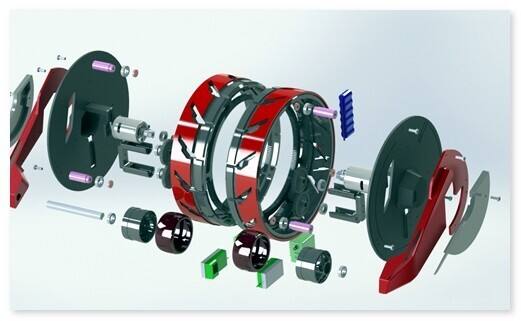

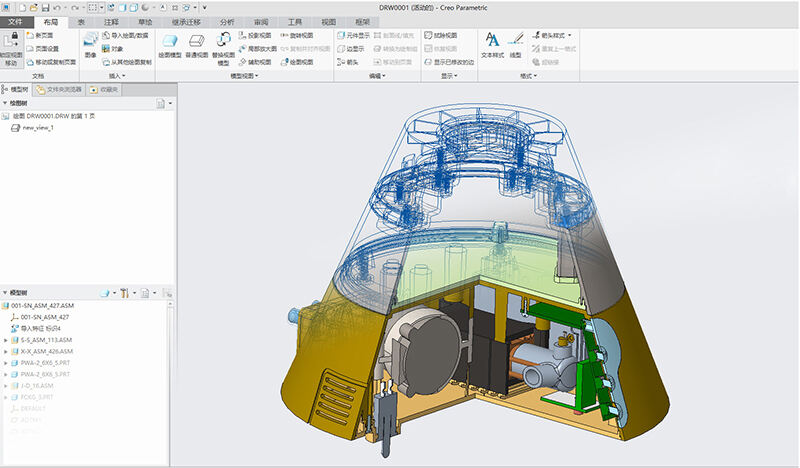

Detailed part design & CAD modelling

During this phase, each component of the product is identified. Detailed engineering revision takes place on them. Tolerances, materials, and finishes are defined after being made to undergo thorough various analyses. CAD drafting technology is also used to create 3D models which forms the key to technology of prototyping. A good explanatory detailed part design Contains detail of components for the manufacturing product.

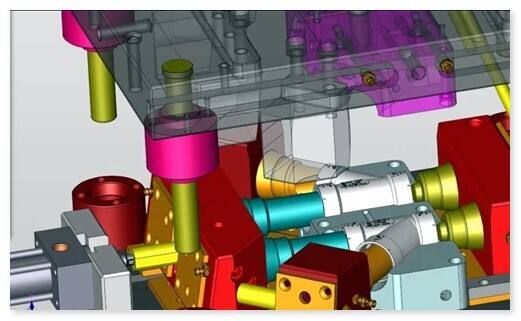

ELECTRO-MECHANICAL Design

Topwell holds a reputation of being one of the leading providers of Electro-Mechanical product design services in china. Electro-Mechanical Modelling is carried out to model and simulate an electro-mechanical system and thus its physical parameters can be examined before the actual system is built. The model is revised and enhanced till all decided conditions are met. This helps the client to develop flawless and accurate product at affordable prices, with shortest possible design lead time.

Mechanical Product Design

Our mission is to help you succeed by driving successful new products to market with a combination of efficiency and innovation. We provide product design services starting from concept and ideation to the complete device design. This includes Industrial Design which we provide best in class look and feel of the product features. We create effective Product experiences through design thinking. The design includes complete structural design, Stack-up design, Tolerance analysis, and material selection, DFMEA, DFM and DFA. One of the Design Integrity’s most valuable tools in new product design is the failure modes and effects analysis (FMEA). Our integrated FMEA process forces the project team to look at the design from a "devil’s advocate" point of view, zealously trying to uncover potential weaknesses or failure points and correcting them as early in the project as possible.

Plastic Injection Mould Design

Having enormous domain expertise, our excellent engineers are earnestly engaged in offering flawless Mechanical Product Design services to our clients as per their requirements at competitive prices. We design from specs provided by conceptualising the product from starting towards the set goals using cutting edge tools, and by precisely ascertaining the current and future needs of end users. Our methodical and intellectual approach of engineering techniques is unmatched in the industry. During our innovatory improvement sittings with our clients we use prototypes and incorporate clients’ suggestions about function and aesthetics in the Design. As a result; technically accurate decisions are taken to minimize the risks and maximize the refinements.

Prototype Engineering

Prototype Engineering is the essential step of design verification in Product Design. At this stage of the process, engineers make mock-ups of the product to examine and validate the design. It gives them the thorough idea of aesthetics, size, and strength of the product and allows understanding its ergonomic features. Prototype Engineering is used for research and development besides simulation of the actual manufacturing procedure as Prototypes provides the best source of information for designers and engineers. Thus prototypes help the designers ascertain which design concept will work the best.

Structural Design

Structural Design provides the ability to anticipate possible outcomes of the Design and take the suitable decisions to prevent failures. Wide range of Design and analysis activities are carried out including Concept Sketching, 2D Design & Drafting, 3D Modelling, Prototyping, Performance, Safety , tolerance and thickness analyses are also carried out. Prototypes and 3D models are examined using the best of line analytical tools to find out how they fail and glitches are fixed improving its performance.

Product Design

In today's increasingly competitive scenarios, engineering companies are challenged to bring reliable, feature-rich products at competitive prices and with the least development lead time. To address these issues and enable customers to realize their goals, Topwell offers Mechanical/Electro-Mechanical (NPD-M/EM) solutions across all industry verticals. These solutions span the complete product lifecycle, from ideation through design to prototyping, manufacturing support, sustaining beyond production and end-of-life services.

EN

EN

ONLINE

ONLINE