04 Manufacturing technique

CNC

What is CNC machining?

CNC (Computer numerical Control) machining is a subtractive manufacturing process that uses computerized machine tools to create custom-designed parts. Computers use programming code to direct machine tools to cut (subtract) materials. This is until the material forms part of the input design.

Create CAD design

The first thing to do is to create a computer aided design in 2D or 3D format. You can do this by using CAD software. With this software, you can render any part you want with the correct technical specifications. However, there is one limitation. The properties of the workpiece play a huge role in the design and its results. We will discuss this under CNC machining materials.

Convert CAD files to CNC programs

The next step is to convert the CAD file to a CNC-compatible file format. The CNC program will analyze the CAD file to generate the code required for the process. In CNC machining basics, you should be familiar with two types of code. These are G code (geometry code) and M code (machine code). G code controls the action of the machine. For example, it controls how to move, when to move, how fast to move, how to move, and so on. M-code, on the other hand, controls factors surrounding machine capabilities.

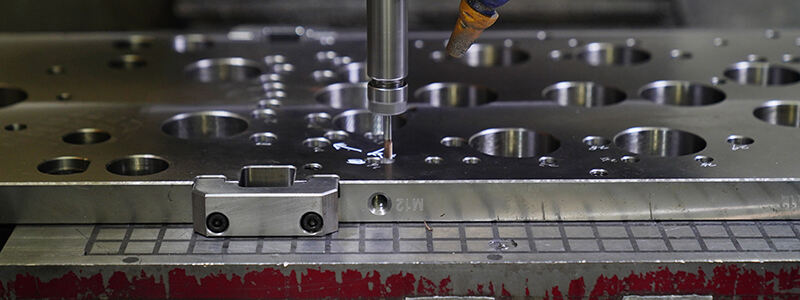

Set up CNC machine tools

There are two ways to set up a CNC machine. One is that you must check the CNC machine to determine its condition. The second thing is to fix the workpiece to the machine. You can attach the workpiece directly to the machine while connecting the required tools and components.

Perform operation

After setting up the CNC machine, you can run the CNC program. The CNC program is the control center of all the actions of the CNC machine. It commands the machine by indicating its actions and actions to get the correct result.

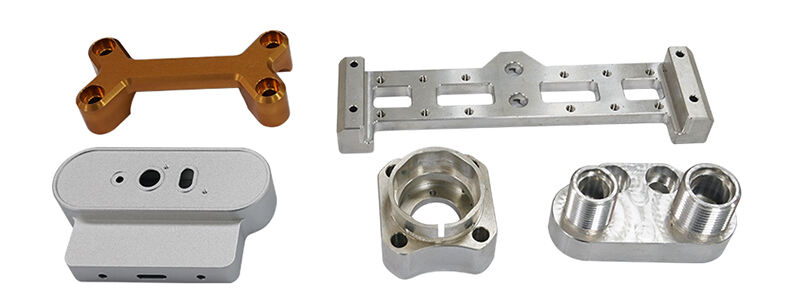

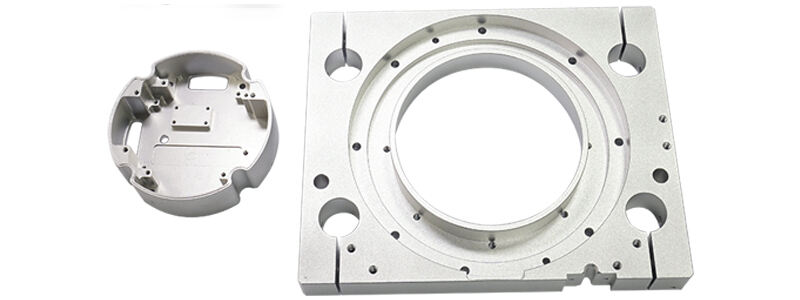

Modern CNC machining, like ours at Rapid Direct, only requires you to upload a CAD file. The CNC program will analyze the CAD file to ensure that the design is feasible. TOPWELL has its own CNC machining workshop; We have advanced multi-functional CNC milling machine; It has absolute advantages in precision, accuracy, multi-function and so on. It also meets the machining needs of CNC parts with different materials.

IML AND IMD

Hard work to win the future, innovation to achieve dreams. Looking forward to the future, TOPWELL adheres to the professional development strategy, seeks truth and pragmatism, pioneering and innovative, and strives for the goal of "creating the world's leading IMD/IML product manufacturing enterprise and achieving TOPWELL's century-old world brand".

TOPWELL is a professional manufacturer of IMD/IML products integrating R&D, production, sales and service. As a dedicated manufacturer of IMD/IML products, TOPWELL is committed to providing customers around the world with leading technology and superior quality IMD/IML products. The company has more than 1,000 employees. Products are mainly used in communication, electronics, electrical appliances, automobiles, medical electronics and many other aspects.

TOPWELL technology innovation advantages, strong R & D team. There are constantly new processes, new materials, surface decoration innovation. It has obtained 13 national patents and become a national high-tech enterprise. Technological innovation is TOPWELL's core competence.

Embodied in:

A. IML products can do high temperature PC plastic products, high temperature 80 degrees, low temperature 40 degrees, high and low temperature test boiling test.

B. The industry's first ultra-thin product is as thin as 0.8mm.

C. Regular innovative surface decoration effect.

D. Can do high pressure molding products, anti-edge IML products.

E. Can make IML products with side holes.

F. Can do soft rubber strap IML, is the future trend of bracelet development.

EN

EN

ONLINE

ONLINE