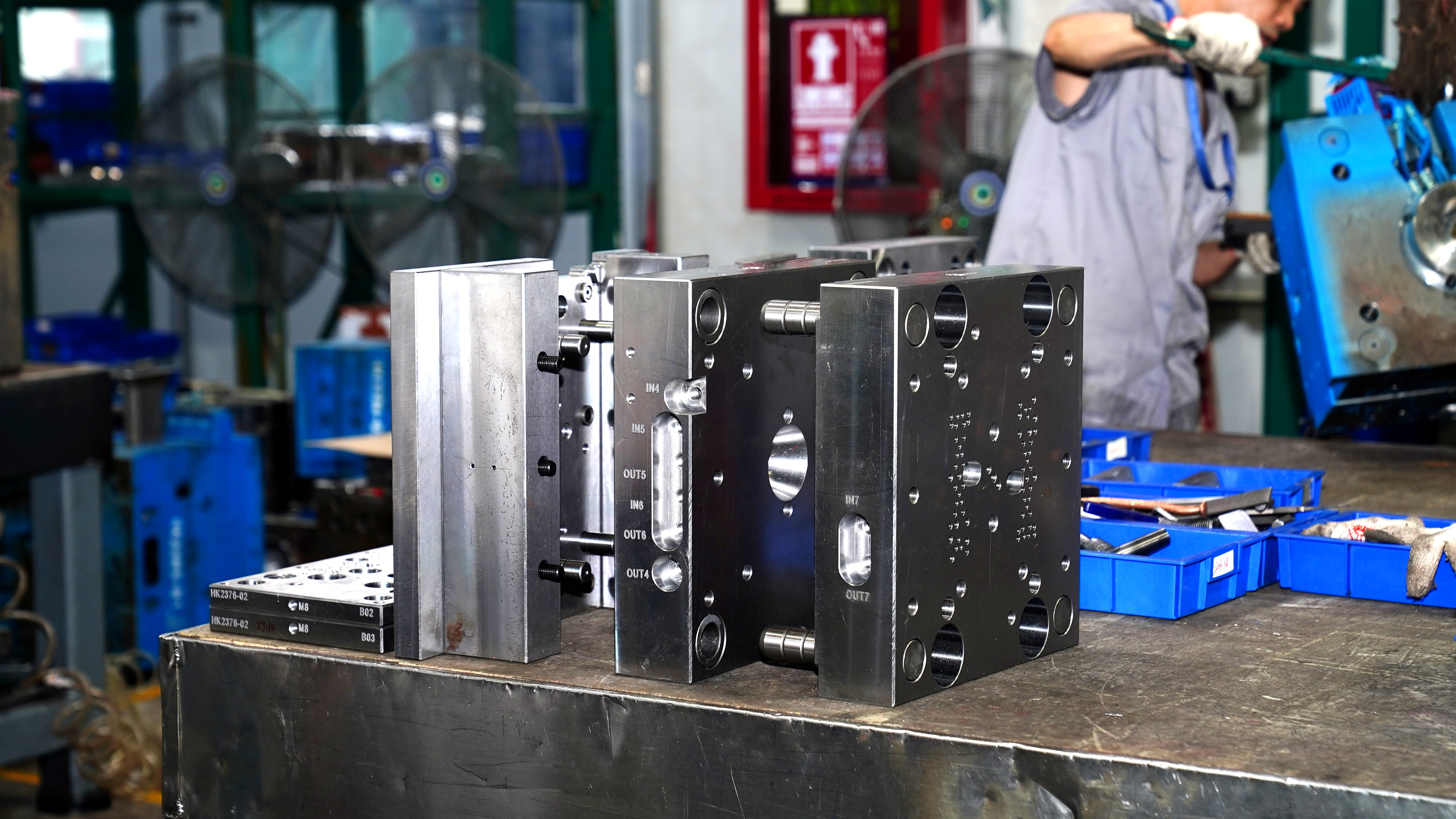

Plastic Mold Injection Factory: The Seven Key Factors for Designing Molds

In the competitive world of plastic mold industry, manufacturers can only seize business opportunities by creating high efficiency at low costs. So, what are the key factors to consider when designing molds?

1. Cost Control: To determine the product's gating system and number of cavities, we must first consider the cost per shot. The most reasonable configuration should be decided based on machine size and expenses.

2. Appearance Determines Destiny: The product's appearance is crucial, thus the position of parting lines directly affects mold processing, venting, and demolding processes. This point must be carefully considered.

3. Leading the Process: The gating method is vital during injection molding.

We need to determine the shape, size, and venting direction of main and sub

runners to ensure optimal results.

4. Breaking Free: Product demolding is a critical step for successful injection molding; therefore, we must identify the correct ejection method and arrange ejector pin positions sensibly.

5. Ever Urgent: Product shrinkage rate and injection time are essential aspects that cannot be ignored. Choosing appropriate cooling or heating methods and cleverly arranging cooling channel locations help optimize production.

6. Rock Solid: Mold lifespan directly affects product quality and sustainable business development. We need to consider factors such as material hardness, thickness, size dimensions to ensure long-lasting durability.

7. Astounding Skill: The level of difficulty in manufacturing cannot be overlooked when it comes to design. By intelligently dividing the components and employing clever wire cutting structures, we successfully overcome any challenges that arise during the production process.

Once these crucial considerations are taken into account, the mold structure becomes clear and easily manageable. With 20 years of experience in the injection molding industry, Shenzhen TOPWELL stands as an expert in mold

design and development. We deeply understand our customers' needs and strive

for long-term partnerships that result in mutual success. Our company adheres to

a mature business cooperation model and management system to ensure reliability, efficiency, and accuracy throughout our collaborations.

This commitment has been our sole guiding principle over our 27 years in this

field.

Join forces with the TOPWELL team and let us create a future together! Together, we can dedicate ourselves to crafting exceptional, durable, and highly efficient plastic injection molds!

EN

EN

ONLINE

ONLINE