What is PCB packaging all about?

Concept and Purpose of PCB Packaging

PCB packaging refers to the installation of electronic components on a printed circuit board (PCB) to provide protection, connectivity, and heat dissipation. It not only directly impacts the performance and reliability of the circuit board but also considers important factors such as component size, pin layout, and thermal requirements.

Common Types of PCB Packaging

1. DIP Packaging: Double In-line Package (DIP) was the earliest type used. It boasts numerous pins and high reliability, making it suitable for most components.

2. SMD Packaging: Surface Mount Device (SMD) packaging is now mainstream. Its advantages include small size, light weight, and enabling automated production. It is ideal for high-density circuit boards.

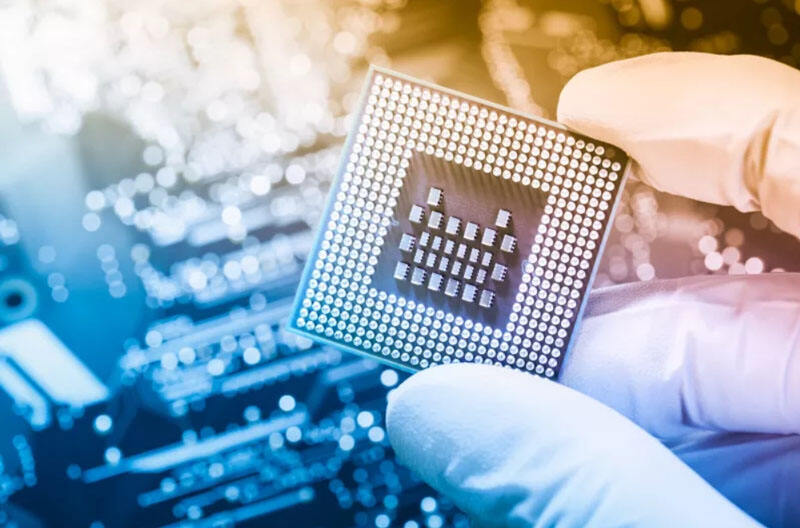

3. BGA Packaging: Ball Grid Array (BGA) packaging offers high density and excellent heat dissipation capabilities, making it suitable for high-performance processors and integrated circuits.

4. QFN Packaging: Quad Flat No-leads (QFN) packaging is compact with minimal pins. It finds applications in small devices and wireless communication modules.

Considerations in PCB Packaging Design

1. Size and Layout: Choose suitable packages and dimensions based on the requirements of the circuit board to ensure smooth component installation and wiring.

2. Pin Layout and Spacing: Properly design pin layouts and spacing to avoid short circuits or interference between pins while meeting the needs of circuit board wiring.

3. Heat Dissipation Design: When designing electronic components, we must consider their power consumption and heat dissipation requirements to ensure they can operate at normal working temperatures. That's why we've incorporated innovative heat dissipation structures and advanced materials.

4. Reliability Considerations: To ensure the long-term stability of circuit boards, we place great emphasis on the reliability of our components. We carefully select suitable packaging types and materials to minimize failure rates and ensure smooth operation of electronic products.

Section 4: PCB Packaging: Evolution and Future

PCB packaging is an indispensable aspect of electronic product design as it directly influences the performance and reliability of circuit boards. With technology constantly advancing, PCB packaging continues to innovate and make tremendous progress. In the future, this field will focus more on developments in high density, high speed, low power consumption, and reliability while also striving for environmental sustainability.

But let's dive deeper into the world of PCB packaging! This technology plays a crucial role in electronic product design - it acts as a guardian by protecting circuits and facilitating heat transfer. As a result, when engaging in PCB packaging, we need to consider multiple factors such as size, pin layout, and heat dissipation requirements. Moreover, looking ahead to the future, PCB packaging will continue to advance by meeting demands for high density, high speed, low power consumption, and reliability. At the same time, we place significant importance on environmental sustainability to contribute towards creating a brighter future.

EN

EN

ONLINE

ONLINE