Introduction:

Mechanical measurement tools are instruments found in several types of equipment determine the proportions of a product, the amount of force applied, velocity, and also other factors which are pertaining to the calculation of real amounts. These Topwell tools have been serving the industry for many years and have been enhanced in the long run, offering rise to more innovative methods for measuring. I will be talking about the advantages, innovation, security, usage, simple tips to use, service, quality, and application regarding the 25 dimension technical available.

Advantages:

The dimension technical have a few benefits, including their cost-effectiveness, precision, reliability, durability, and simplicity of good use. These tools offer an real way efficient of different amounts, meeting the needs of the industry. Also they are in a position to supply a qualification accurate of, this means accurate data for analysis and decision generating.

Innovation:

Innovation has driven the introduction of those dimension technical, leading to the development of more instruments that are sophisticated. Today, the industry has tools that are more complicated, offering better accuracy, reliability, and effectiveness. The innovation of those tools has brought about improvements in to the level known of and integration, which includes revolutionized the measurement procedure.

Security:

The security related to usage of these tools is a must. They should be use plastic injection mold correctly to prevent any risk possible the users. It is vital to own gear protective for instance gloves and goggles, when making use of these tools to avoid accidents. It's also necessary to keep carefully the tools in good shape working adequately maintained to avoid gear breakdowns that could pose security dangers.

Usage:

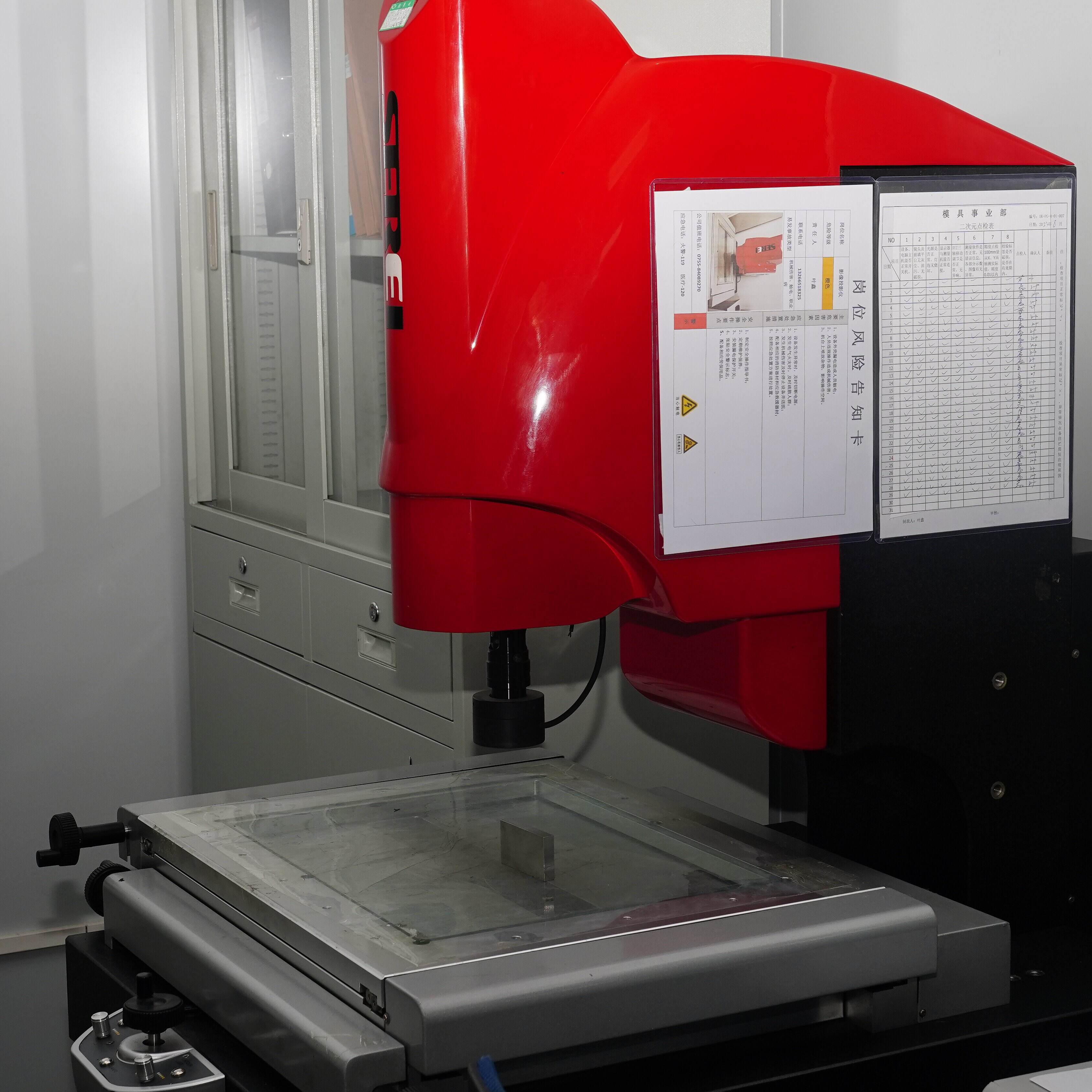

The utilization of these tools is diverse, and their applications differ with regards to the industry. A number of the 25 dimension mechanical include electronic calipers, micrometers, height gauges, surface finish testers, hardness testers, and dial indicators. These plastic injection tools are employed into the automotive, aerospace, medical, and plenty of other industries worldwide.

How to use:

Making use of these tools is dependent upon these devices particular utilized. However, being a rule basic it is crucial to follow along with the maker's directions to ensure the device is used properly. In certain circumstances, training may be important to make certain that the device is handled accordingly. Additionally it is necessary constantly to utilize the unit that's true the task to achieve accurate outcomes.

Service:

The service rendered by these tools is essential, plus they should always be serviced regularly. This process ensures that the tools are maintained in good shape working preventing prospective breakdowns, and extending the lifespan for this tools.

Quality:

The quality of the equipment is a must. The gear must certainly be of good quality to provide accuracy, reliability, and durability. Poor quality tools may result in measurement mistakes, hindering the process decision-making the industry. It is vital to make sure that the tools utilized stick to industry standards.

Application:

The applications of mechanical dimension tools depend on the industry, and they also differ based on the tools getting used. These plastic injection molding companies tools are acclimatized to determine various areas of an automobile, for instance brake rotors, transmission gears, and engine parts for example, inside the automotive industry. In to the aerospace industry, technical measurement tools test areas of an airplane to determine their structural integrity.

ONLINE

ONLINE