Why Testing Car Molds for Water is actually Essential?

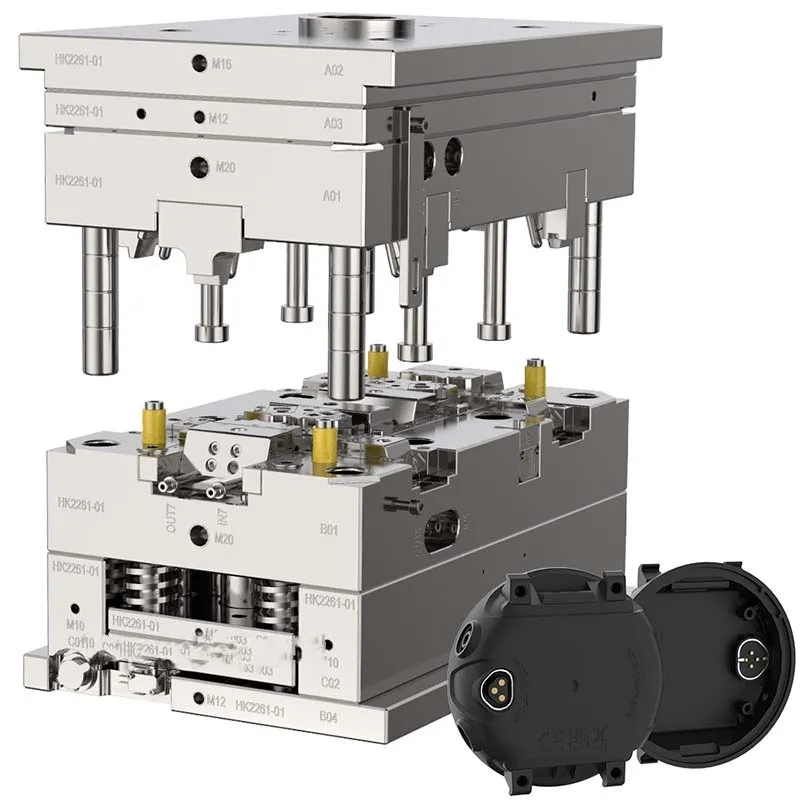

Car molds, likewise referred to as tooling, could be a part is actually important of production treatment for vehicles. They are actually utilized to produce the different elements comprise a vehicle, with the body system to the motor. There are actually a number of advantages to car is actually using, consisting of development, security, as well as quality. Nevertheless, prior to these molding parts could be used to produce elements, they require to be actually evaluated for water. We'll check out why screening car for water is essential as well as exactly how it can easily enhance the general quality as well as security of vehicles.

Benefits of Utilizing Car Molds

One benefit of utilization car molds by Topwell is actually their ability to produce continuous as well as elements being actually precise. Unlike conventional methods of production car parts, like for instance casting or even welding, molds provide a higher degree of repeatability. This enables producers to produce molded part along with the same shapes and size each time, prominent to increased performance as well as much more secure vehicles. Furthermore, molds are actually created to create forms that are actually complicated styles, enabling higher development in car style.

The Significance of Screening for Water

Nevertheless, prior to a Car Mold might be utilized to create parts, it needs end up being evaluated for water. Water in a mold might trigger a number of problems, consisting of corrosion as well as rust, which can easily top to element failings as well as safety and safety issues. Furthermore, water in a mold can easily trigger the part to warp or even breather throughout the production procedure, prominent to quality is actually additional.

Screening for water in a mold includes utilizing a procedure referred to as dielectric testing. This treatment utilizes an electric present to spot the existence of water in the mold. If water happens, maybe eliminated using different techniques, consisting of vacuum cleaner drying out or even a desiccant. When the mold is actually without water, it allows you to produce parts securely as well as easily.

Enhancing Quality as well as Security

Through screening car molds for water, producers can easily improve the quality as well as safety and safety of this particular electric motor vehicles they create. Water in a mold can easily trigger element failings, which can easily have actually repercussions which could be major like for instance mishaps or even injuries. Furthermore, by utilizing dry molding service, producers can easily produce elements being actually much a lot extra constant as well as precise, leading to vehicles that are actually better-functioning. This quality is actually enhanced furthermore lead to higher customer complete fulfillment as well as brand name support.

Exactly how to Utilize Dry Molds

When the Car Mold was evaluated for water and it is dry, it could be used to produce parts. The mold has plenty of the suitable product like plastic or even steel, and after that either heated up or even cooled down to collection the item right in to the preferred form. When the appropriate part was produced, it could be eliminated coming from the mold as well as examined for quality. If any type of pressing problems lies, the mold is actually changed or even fixed as required. By utilizing dry molds, producers can easily produce high-quality parts that satisfy their precise specs.

Service as well as Application

Testing car molds for water is actually a part is actually important of production procedure for vehicles. It guarantees that the appropriate parts produced using the molds are actually risk-free, continuous, as well as of quality. Because of this, lots of mold producers has actually assessment solutions to their clients. These solutions allow you to examination molds which could be new to test current molds for water as well as various other quality problems. Through partnering through possessing a mold manufacturer that provides screening solutions, producers can easily ensure that they're creating parts that consult with the greatest requirements of security as well as quality.

ONLINE

ONLINE