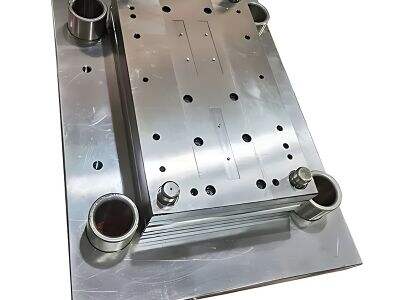

The Wonderful World of Die Casting Mold Design, in UK! Application: Die casting mold design and development play a critical role in the manufacturing industry. It is a method in which the molten metal injected into a customized mold to produce components of diverse shapes. These high pressure, specialized machines create those ADA architectural sign designs with speed and details as well as efficiency. The UK has an established history of die casting technology that can be leveraged by manufacturers across different industries. Pros and Cons of Die Casting Mold Design & Development in the UK:There are many positive aspects of utilizing die casting mold design & development at UK. Cost-Efficient is one of the biggest benefits A booming manufacturing sector in the UK ensures that raw materials are plentiful, skilled workers available and up to date machinery can be found. Die casting uses these resources to allow for fast, accurate creation of complex parts. This is optimized for mass production and becomes a cost-effective solution over other manufacturing processes out there with the ease of being able to create large runs.

Ingenious Design and Development of Die Casting Mold Ingenious mold design is one of the most important parts while Ealing manufactures that are working with die casting UK. New technologies are enabling countless industries to produce goods more efficiently, with less waste or negative impact on their environment. Such advances include a robots that can perform tasks from part recognition to sorting, enhanced cooling systems driven by simulation and analysis and strengthened productivity through creative monitoring software. Ingredients from Die Casting by the Enterprises have been known for their innovative approach and are proving no different when it comes to die casting, with some remarkable findings. Safety and Utilization of Die Casting Mold Design & Development: Safety is considered as prime concern in UK when it comes to die casting mold design and development for which all machinery have strict regulations along with regular safety check.

The machines a part of the process have been designed to pose minimal risk and ensure no injuries would occur in case..." - James Devaney The goal is to protect the operators and other workers while keeping component quality high. Die casting mold design and development is a good industrial way today, both the workers and manufacturers need to operate safe alert when using it. Die Casting Mold Design and Development Applications:Using die casting mold design and development process is quite handy to use. It starts with the designing of a die or mold according to dimension and shapes, which are necessary for particular part requirements.

The die/mold is then heated and hot melted metal are forced into the mold in a pressure system. The metal in the mold then cools down and solidifies, creating the completed part. At the end of process, any additional material is trimmed away and finished product undergoes a series of quality checks. Die Casting Mold Design and Development, Service & Quality:Quality is everything with Die casting mold design and development in the UK. We implement safety and quality control checks, so that the parts which are produced meet the highest standards. Our state-of-the-art technology and expert operators will provide your business with accurate, consistent die casting mold design and development for each project. Additionally our excellent customer service ensures all of clients are satisfied with performance. Die Casting Mold design & development applications in the UK:- There are a vast variety of industries Die casting Mold design and develop is used, including Manufacturing, Aerospace ( Aircraft Interior Parts ), Automotive sector ( Engine Components )and Marine industry etc.. This includes parts for automotive, construction equipment, electronics and a variety of other products. Die Casting Mold Design and Development - Die casting mold design & development is important to ensure that large-scale production of complex parts with high quality precision, at minimal unit cost which makes it one among the best adopted techniques in manufacturing.

In Conclusion To summarize, Die Casting Mold Design and Development is utilized to incorporate a crucial technique in the industrial manufacturing process within different sectors of UK. The advantages to the process, as well as competition in technology, safety protocols and how materials are tested lead to a necessity for many uses even still today - from house products you use every day being made with injection molding machines. This is a tool in the hands of manufacturers to improve their productivity and be cost-efficient. UK has always been a powerhouse of the die casting tool designing and development, which leads to UK having solid manufacturing sector, plus good name for economical cost as well as precision.

ONLINE

ONLINE