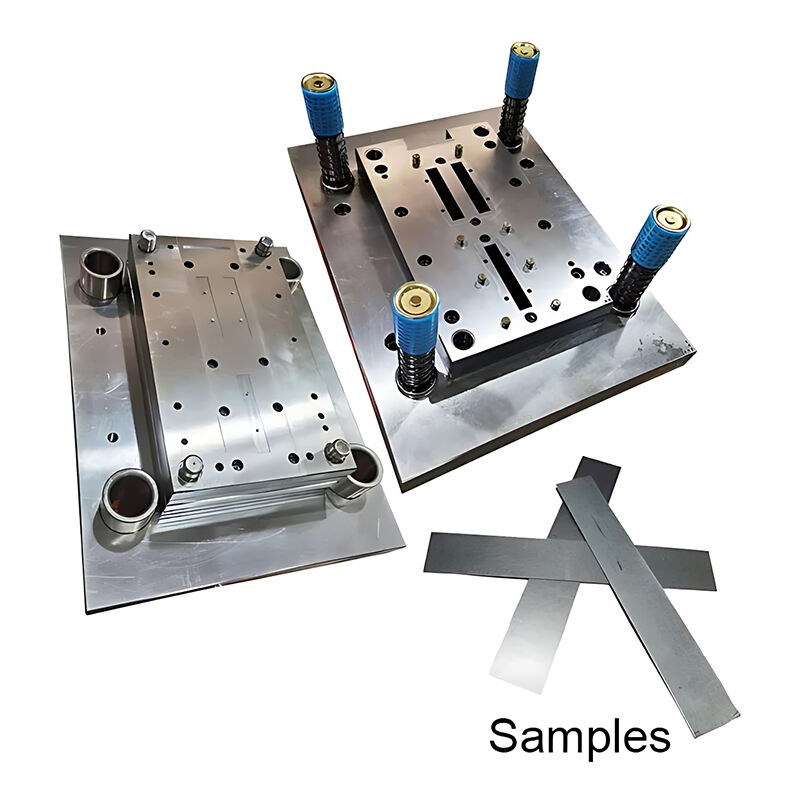

Did you ever wonder, as cars and planes glide down our highways, phones tap away in a blur of social media activity or that medical scalpel makes the perfect incision...how those metal parts are generated with such speed and precision? That comes directly to precision metal stamping! This elaborate process whisks thin sheets of metal all through the factory, where it gets punched, bent and formed into precise components. This technique is fundamental in many different sectors including automotive, aerospace, electronics and medical devices. Precision metal stamping services offer a distinct technological and operational advantage with high-tech facilities and manufacturing methods to help manufacturers enhance their competitive position, productivity gains, lower cost structures per unit scheduled volume capacities while ensuring the highest possible level of product quality.

How To Improve Your Manufacturing Process with Metal Stamping

Ultimately, we will work with you to enhance what is fundamental about our metal stamping services-capability enhancements in manufacturing. We fit right into your production workflow, use design consultation to help with part designs for stamping and deliver on a Just-in-Time basis so that you have better inventory management. This not only reduces material waste and production lead times but also assures that our process ensures reproducible quality in your product, boosting overall operation efficiency. You will also get a solution that is custom made to the specifications you provide us, which focuses on not just meeting your project requirements but exceed them in all possible manners.

How Custom Metal Stamping is Helping You to Solve Complex Design Challenges

Our custom metal stamping solutions can take on the most intricate of designs with ease. We do the impossible If you have a challenging design, we can make it reality. By utilizing computer-aided design (CAD) and finite element analysis (FEA), we perform stamping process simulations to further be able to predict any potential known issues early in the development cycle prior production. It is a methodology that allows us to make exacting, multi-level and 3D appearance components some of which would be hard if not impossible for traditional stampings. Embracing Complexity enables our clients to innovate and explore new worlds with their product designs.

High-Volume Metal Stamping: Combining Speed and Accuracy

Keeping the line moving while still hitting tight tolerances is a high-volume metal stampers bread and butter. Capable of high volume micro tolerance manufacturing in our state-of-the-art presses with auto feed and inspector systems. We optimize cycle times with robotic and machine learning algorithms to provide consistency of output throughout long production runs. This balance of speed and accuracy ensures that your high-volume orders are fulfilled on time and with an eye for quality. Therefore, it paves the way to a faster time-to-market and equips you with an edge over your competitors around the world.

State-of-the-Art Stamping Services That Are Revolutionizing Innovation

Staying up to date on all things technological is a necessity in the world of manufacturing, particularly with how quickly technology changes. Regular investments in high-tech equipment like servo presses and laser cutters set us up for the best-in-class service you can expect. These capabilities also allow us to process exotic materials such as titanium and Inconel, which are common in aerospace and medical device manufacturing where stringent requirements exist. In addition to our Industry 4.0 capabilities like real-time monitoring and data analytics, new horizons of the stamping process are visible that allow predictive maintenance - making a quantum leap in operational efficiency possible only by Bihler's servo technologies.

Key to Modern Manufacturing: Productivity and Affordability

Precision metal stamping is the cornerstone of efficient and cost-effective modern manufacturing. Stamping consolidates multiple manufacturing processes into one operation, significantly reducing labor and material costs versus alternative machining or fabrication methods. This results in the ability to create complex parts with a single press stroke using optimized tooling designs, which increases productivity and minimizes costs per-part. This results not only in increased profits, but also supports sustainability by minimising energy consumption and waste. Industries are adopting methods that are leaner and meaner yet greener, so the precision metal stamping serves to be a game changer in this pursuit.

In summary, precision metal stamping services fuel the manufacturing processes by bring together technical prowess, flexibility and cost effectiveness. Through partnership with a provider which is pro-innovation, customisation and in tune to customer requirements manufacturer can experience the competitive growth agility within its segment when combined. With ongoing advancements in technology, precision metal stamping will continue to play a significant role in the future of manufacturing.

ONLINE

ONLINE