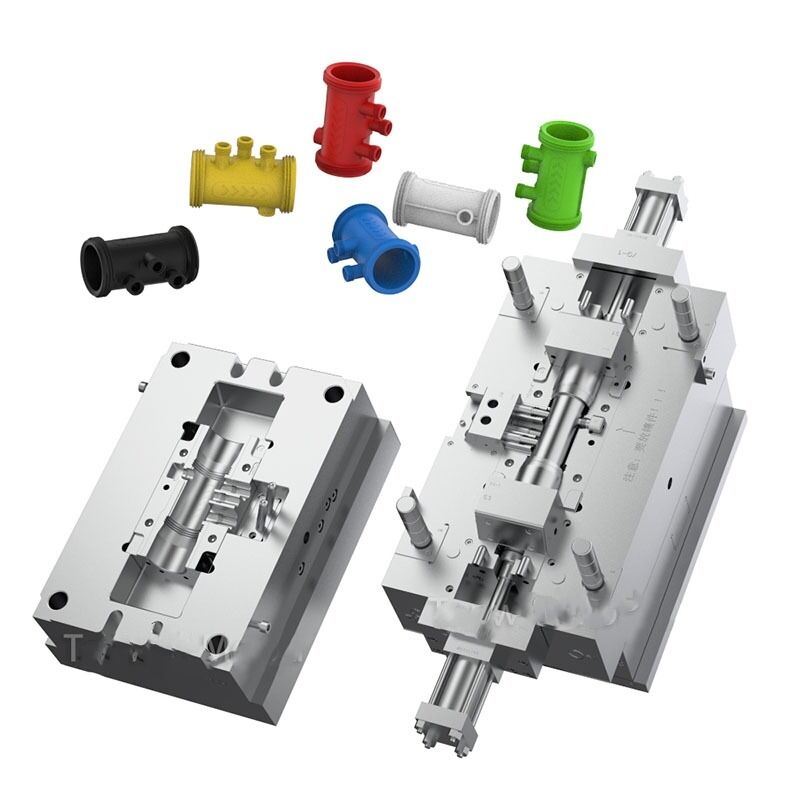

Quality Control Within Plastic Part Manufacturing

Many pieces are made at a time when manufacturing plastic parts. Which is why it matters so much to make sure those pieces are top-notch. The brand likewise has quality control strategies to ensure that the items are sheltered, uniform and solid as well.

Importance of QC

The quality control is very important for the mass production of plastic parts. Before it can be injection molded, this material must undergo a sequence of melt filtration processes to remove all impurities. This makes it harder for manufacturers to ensure that their finished products are of the highest possible quality without stringent measures.

Quality Control Approaches

Manufacturers have several tools at their disposal that they can use to improve the repeatability and quality of plastic part production. Effective methods include monitoring process parameters, using high-quality raw materials and checking final products for defects. Here are some specific guidelines for a better plastic parts production:

Choosing from the Best Raw Materials: Use only those excellent materials of in-reputed brands which can increase product lifespan and suffice production cost.

Training Workers:Machine operators should be trained well so as to keep a regular and defect free production.

Machine upkeep: Regular servicing of machines prevents contamination and defects, so that the production space is clean.

Process control: If the process is maintained consistently, it will produce compliant parts in terms of dimensions and surface finish requirements.

Traceability of Process Variables: Monitoring process variables in injection molding helps catch defects at early stage

High-Quality Tooling Equipment: High quality tools ensure greater accuracy and avoid maximum rejections.

Being Up-To-Date - Proper knowledge about the industry standards helps in improving production efficiency.

Inspections: Frequent inspections carried out by experienced operators can decrease the chances of defects during injection molding.

Final Check: Every product is cross-checked prior to dispatch, all products are guaranteed in perfect condition at the time of purchase.

How DMS Can Enhance Quality

Leveraging centralized, paperless management platforms to control production data not only affords visibility of records but also aids in tracking and storing information efficiently.

Improving Efficiency and Quality with Automation

The loads in batch production processes benefit from automation, thereby introducing increased precision, cost efficiency and elimination of errors. During manufacturing, surface defects can be detected by automated systems (tracking temperature and cycle time), reducing the number of defective products.

Quality Control Equipment Technologies

Finally, it is important to note that without the use of advanced technologies like Artificial Intelligence (AI), you simply cannot achieve consistency and verification. Using AI on data concerning the injection molding process monitors performance in a very accurate manner and foresees complications beforehand.

Because of this, it is extremely important to keep the quality standards high in plastic part injection molding. Manufacturers need to focus on quality control standards that improve the life and endurance of a product Manufacturers now have a myriad of options available to help them optimize their quality control systems, thanks in large part due to technology advances and effective quality management methods.

ONLINE

ONLINE