Manufacturing from an Environmental point of view

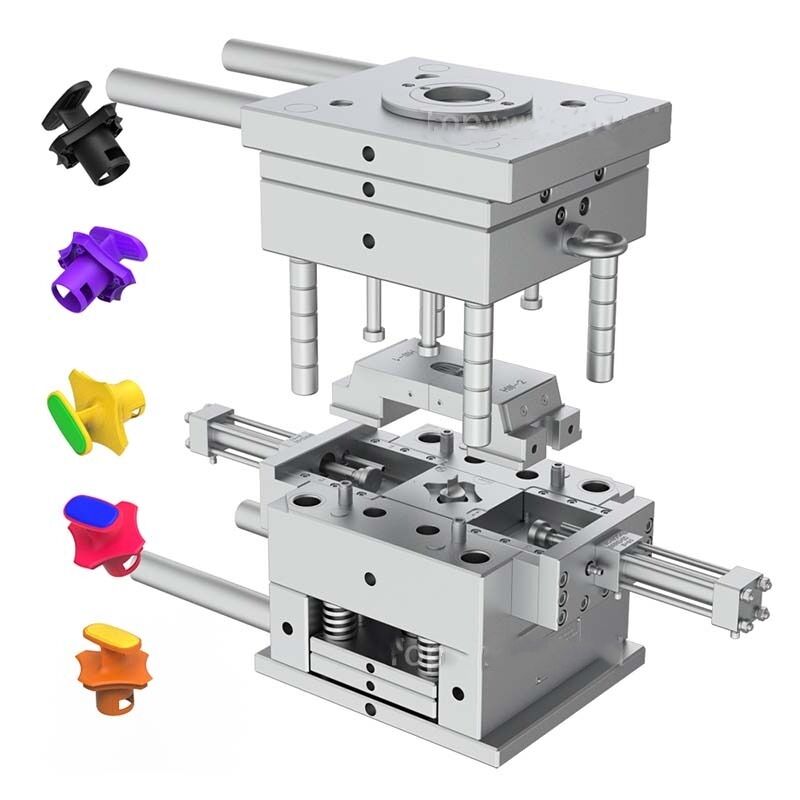

Manufacturing is the production of goods, but it also has some negative impact on the environment if not properly manage. Today, we are going to explore how companies can keep nature in mind when making the things that they make.

Top Environmental Factors in Manufacturing

Products are made, materials such as plastics, metals and chemicals etc. If not handled right these materials are likely to wreck the environment. Here we look at some of the key environmental factors that businesses should take into account:

Production of certain goods requires a large amount of energy. Forcing companies to lower the energy usage of their equipment and processes.

Waste of Material: The production also creates material waste such as plastic scraps, & so on. Overcoming this problem is possible for the companies as they implement recycling programs and finds new means of utilizing waste.

Harmful emission :Like that of the manufacturing can release harmful emissions like greenhouse gases. Mitigating these emissions is becoming more and more important for companies.

Water: Manufacturing processes sometimes require a lot of water for cooling and cleaning. Adopting water-saving measures and recycling practices will help companies minimize their overall water use.

Going green

Here are a few eco-friendly techniques companies have adopted to limit their environmental harm in manufacturing:

Material Selection: The selection of material can help to reduce the environmental impact by choosing green materials like biodegradable plastics.

Energy efficiency: The use of energy-efficient import can dramatically reduce production cost from the amount of energy required for its operation.

Reduces Waste: Lean Manufacturing principles help to reduce waste during the production process.

Solving Environmental Problems

Manufacturers have issues that relate to concerns surrounding environmentalism, such as implementing enviro-friendly manufacturing options like disposing of materials and wastes in ways which prevent contamination.

Cost vs Environmental trade-offs

Although, the eco-friendly methods cost a bit higher at one time but in future its environmental advantages are too high against these costs. Companies must also consider the economic as well as environmental sustainability in decisions.

Original Strategies of Environmental Sustainability

New approaches can reduce the environmental footprint of manufacturing.

Energy: Employ renewable energies such as Wind or Solar power to lessen the environmental load due manufacturing.

Closed-Loop Systems: These systems recycle either water or air, ideally cutting back on waste and costs.

Design for Cradle-to-Cradle: Create products that can be easily broken down and recycled, rather than thrown away.

To sum it up, even though we should be concerned about the impact of manufacturing on our environment and adopt eco-friendly practices as much as possible to alleviate these concerns but at any rate you can not truly eliminate this concern rather work upon addressing them, balancing out the costs and benefits which a business is responsible for while implementing some strategic way forward in advancing your product lifecycle going into future generations having assurances that they would create an equal & sustainable world.

ONLINE

ONLINE