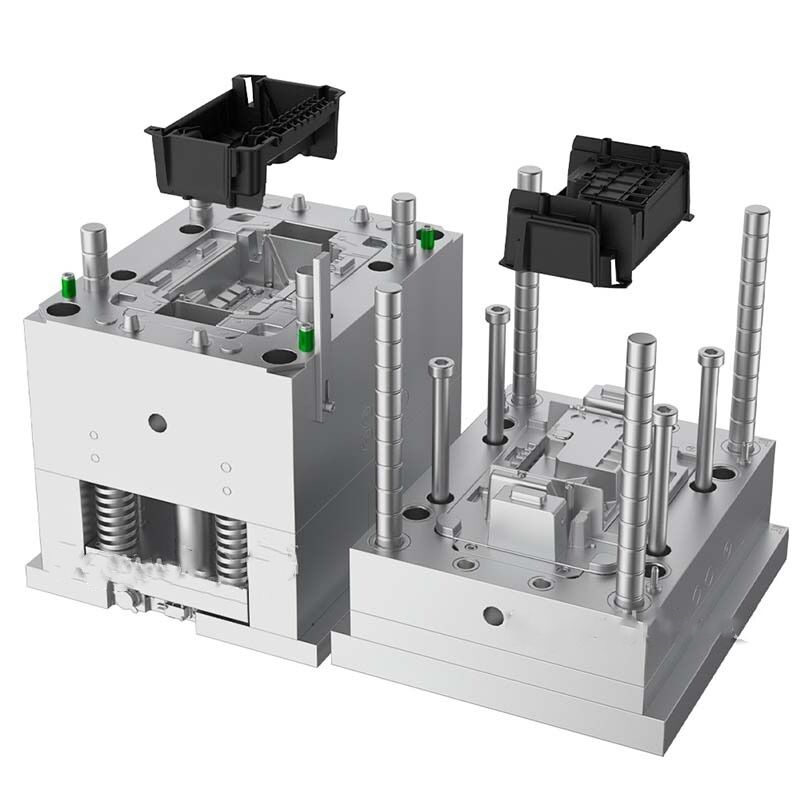

Plastic injection molds play a vital role in the manufacturing process of variety of products, today. Due to their versatility in the production of high volumes for identical parts across different sectors like automotive, medical device, consumer goods or electronics makes them very popular. Its use complex features and mould which would have been almost impossible to make otherwise. Molds are one of the most important applications for this material because tooling such as molds plays a fundamental part at producing parts with complex feature done in no other way possible.

By this brand - The best thing about plastic injection molds is that they are really cost-effective and versatile. These molds assist in increasing the design possibilities and at the same time allowing manufacturers to reduce waste, which would make their products significantly more eco-friendly as well cost-effective for making. This advantage of reducing cost, because then you can invest more in innovation and that enables to keep technology updated which is a must-have need today considering competition we are getting where everything from automation to digitization happening at an incremental pace every-day.

Furthermore, the flexibility and versatility of their use in production is another reason why plastic injection molds are still popular. The capability to produce complex and intricate parts that would be otherwise very difficult, if not impossible to obtain via other possible methods of manufacturing. This tun-ability enables materials scientists and engineers to optimize the properties for a specific application, which results in higher value products.

As a result, nowadays plastic injection molds are integral to the manufacturing process. nearing the ability to help manufacture low cost, high quality goods on a mass scale. Plastic Injection Molds make sure to guarantee the precision, accuracy and cost-effective process of production. In the manufacturing line, these molds are critical apparatuses and this will be their way to decision sometime down the road.

ONLINE

ONLINE