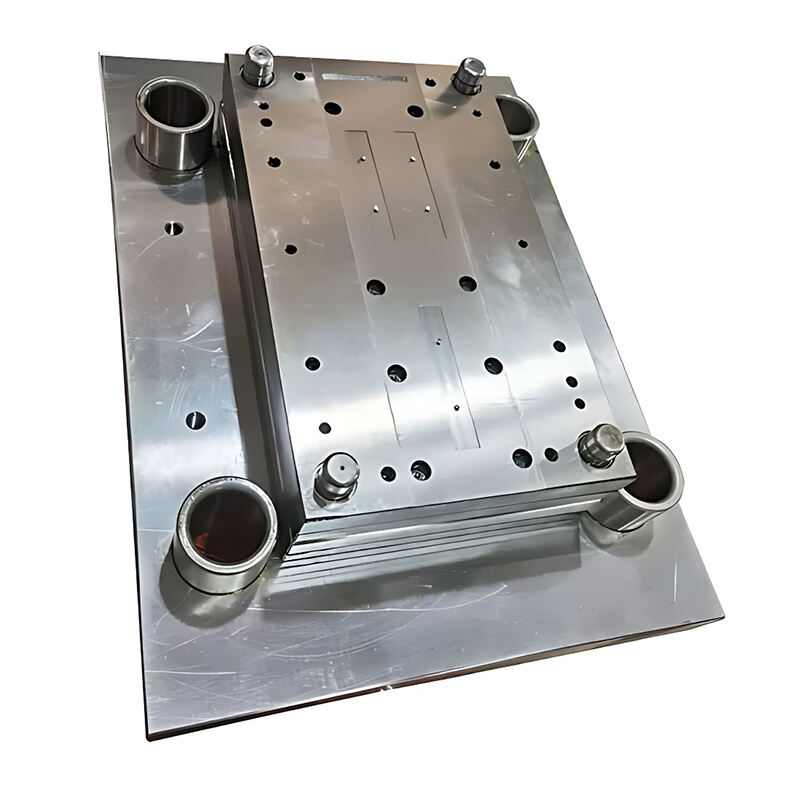

Efficient and Cost-Effective Production of Plastic Parts for Companies With affordable methodologies and solutions in place, manufacturers can enhance their production processes with minimal wastage of resources - reducing costs without any compromise on quality. Here are a few of the key approaches to accomplishing these goals:

Optimize Machine Efficiency - A critical approach to making machines more efficient Ensure that your equipment is well-maintained, maintained properly and at the right time replace old parts as required while implementing energy-saving technologies. Reduced manufacturing costs and lower energy consumption are just a few of many benefits.

Reducing The Load On Workers: Streamlining operations within the production workflow is another core pillar of achieving this. If the right redundancies or inefficiencies are detected and end up being removed this can lead to major cost savings. Automating this strategy and optimizing workflow to shorten production times, reduce labor costs.

Waste less; use less plastic: The next important aspect you need to take care in cost-effective plastic injection molding is going green. Strategies such as aligning in-feed proportions, optimizing shot size & incorporating recycled content is probable areas where significant material costs can be realized. Being conscious of material use allows manufacturers reduce the financial waste plastic leaves in its wake.

Do It Correctly the First Time: Quality control is a key aspect to cost-efficient production. It is the quality control system that helps in preventing production errors for minimizing defects, recalls and returns. Manufacturers can save in costs of rework, scrap and disposal by maintaining a laser focus on quality - ultimately resulting in saved dollars.

By following these low-cost strategies, manufacturers will be able to save money and stay relevant in the fast-paced manufacturing industry of today. For any business to survive in the market, it cannot do without these strategies which majorly include maximizing machine efficiency but not compromising on operations that are too complex nor complicated and need streamlining as well therefore reducing material waste focusing more towards quality control.

ONLINE

ONLINE