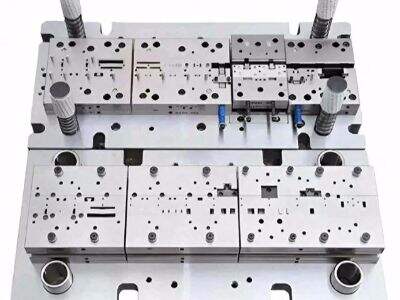

Since the demand is high, exporting good quality molds could be an arduous task. However, the process of making molds cannot be done evenly and it may become a problem to make all types of molds that continue up to customer requirements internationally. Since the countries have different specifications and requirements, mold makers need to work out with customer exactly what they want. With some best practices, tips and strategies it is possible to export molds successfully. In order to make the export of molds smooth, Topwell has come up with some basic ideas for Molding company.

The Big Challenge for Exporters of Molds

In export molds, one of the significant challenges is to satisfy different needs of customers from other countries. Every customer will have a unique need based on their industry/ usage. This is why it becomes really crucial to form Molding manufacturing which might be suitable for just about every customer. Further, molds produced in one country may not function as effectively in another because of variances such like weather and climate have on the work of a mold. It is necessary to cater the demand of any specific of customer, however in order not just meeting a single or dual part but all universal rules and standards that are practised around globe. The process could be complex, but it is crucial for the long-term success in Molding parts exporting.

Best Practices in Exports Molding

Some of the better practices for these exporters to make molds that people will want all over this great small world. Much more important is designing a mold that fits the industry of your client and seeding with appropriate standards. That means it has to know the industry's needs in order for mold designers. It should also be noted that maintaining a high precision for the mold and providing anti-breaking capability is critical. Heightening to the customer budget is a always good policy but reducing the quality of mold just for his sake was not acceptable. Satisfying the level of quality required by a customer is essential because it can result in long-term relationships and repeat business.

Mold export experience sharing

Exporting molds requires careful planning and thinking to have a successful plan. A good suggestion is to form relationships with clients and provide support even after a sale It helps to build trust and a positive relationship with customers which is crucial for establishing long-term relationships. High-quality molds that are delivered promptly and offered at competitive rates can set you apart from most others in the field as well. Being dependable and consistent can go a long way in creating goodwill.

Some other key things are to be updated with the latest trends and ideas in the industry which can boost mold production. It also involves keeping up to date with current technologies and techniques for improving the quality of molds. New technologies such as injection molding simulation and mold flow analysis can be used by manufacturers to better the quality of molds. Adapting to this technology will help factories produce more molds faster and still maintain high quality.

Tips for Successful Mold Exports

For mold exporters to overcome difficulties in exporting, there are various concepts they can use. A good tip is to collaborate with a trustworthy molds manufacturer accustomed to exportation. They help in the designing, manufacturing and shipping of molds while ensuring their quality. Working with a factory that knows the ins and outs of exporting can save you time and money, which will make your experience smoother overall.

It can also provide additional services such as shipping assistance and training that sets the exporter apart from his competitors. These extra service can let the customers feel more comfortable and satisfying, thus become repeat buyer or referral in future.

If you have read that out, then here is the second part of how technology changed mold exporting.

Technology has improved various industries and mold making/exporting is not an exception. Computer aided design (CAD) and 3D printing have made it to where the process of producing molds is far more advanced. Manufacturers can design 3D CAD models rapidly with the help of these technologies and as a result, they get better molds. Smart sensors can also be used in the manufacture of equipment, which makes it possible to reveal worn out and defective form when machining parts. This will help increase the quality of production.

Mold exporting can be another bottleneck, and you may consider using cloud-based tooling solutions as well. They used to track The whole Process In making molds (start + end Products). This allows exporters to keep an eye on all design changes, communicate with clients like never before and assess loadings status at any time. When customers can easily access all this information, the relationships you have with your clients will be strong and positive because they feel informed, acknowledged.

To sum if up, it is difficult to export high-quality molds but with the best practices and tricks of trade you can run successful business. Creating molds is a meticulous and today-consuming process that need to be flawless throughout. That is how, with the best of technology Mold Exports can achieve and even exceed customer satisfaction. Topwell has built good reputation to make high quality molds and export them worldwide. Topwell has the experience and they can help other companies to be able, offering their guidance about this export field.

ONLINE

ONLINE