Are you still wondering what products can be produced through injection molding

Are you still wondering what products can be produced through injection molding? Don't worry, I'll tell you!

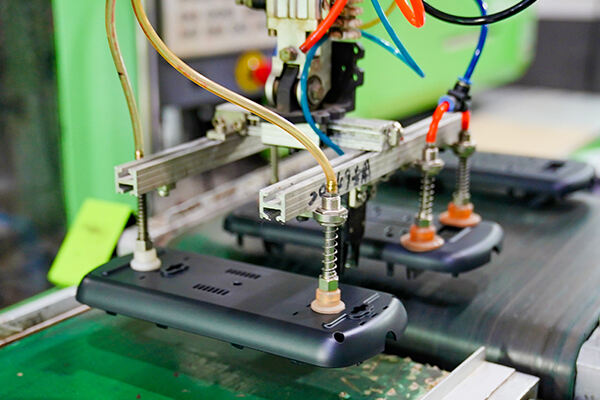

Electronic casings

Electronic casings are the "weapons of choice" in injection molding. Whether it's a remote control, computer, television, medical equipment, or any other device manufactured using injection technology, they all rely on this manufacturing technique without exception.

Through injection molding technology, we can effortlessly create various customized plastic casings that provide sturdy and aesthetic protection for electronic products.

The world of toys

The world of toys also relies heavily on injection molding. It allows for the creation of lightweight and durable toy products. From different sizes to a wide range of colors, they have a competitive advantage. Just like Lego brand toys where each block fits perfectly together after precise molding,

these intricately designed products bring joy to children as they enjoy the process of creating and exploring.

In agriculture

Injection molding also plays an important role in agriculture. You may be curious about how it integrates with agriculture; well, it helps us produce the plastic products needed in this field. These products can be applied in cultivation, breeding, and other areas to enhance efficiency and productivity.

Household components

You may not realize that many common household items we use every day are produced through injection molding. Just imagine the molded bottle caps, containers, components, and utensils that accompany us throughout our daily lives – all owe their existence to the wonders of injection technology.

So as you can see, injection molding has proven its versatility time and time again across various industries. Its ability to produce sturdy yet aesthetically pleasing electronic casings makes it an essential manufacturing technique for electronic devices. In the world of toys filled with endless possibilities for creativity and exploration,injection molding ensures their durability while maintaining their intricate designs. Additionally,agriculture greatly benefits from the efficiency-enhancing plastic products created through this technique,and even our everyday household items owe their existence to the incredible advancements of injection molding.

Mechanical and automotive components

Inside cars or transport vehicles, there are numerous internal and external components, such as bumpers, dashboards, radio control devices, cup holders, and more. Have you ever wondered how these seemingly simple parts are brought to life step by step through injection molding? Just take a look at their exquisite yet sturdy appearance; it's like dressing up the vehicles in glamorous outfits.

Healthcare industry

Injection molding plays a critical role in the healthcare industry. Next time you visit friends or family at the hospital, pay attention to the widely-used products surrounding you. Medical syringes, surgical tools, and more - all rely on injection molding techniques. To prevent the spread of bacteria or diseases, many healthcare products are disposable. And behind the scenes, injection molding silently empowers this industry to safeguard our health.

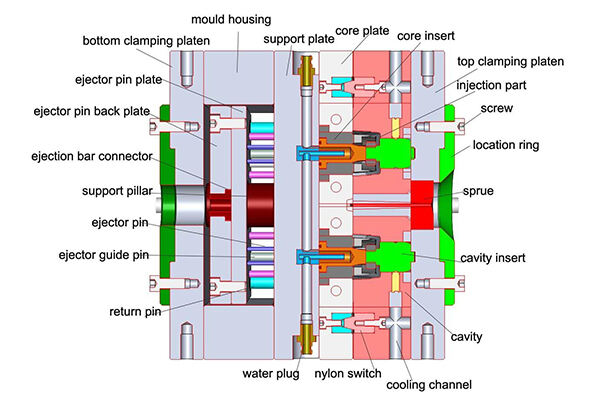

Injection molding is not only widely applied in commercial, industrial, and consumer goods production but also brings endless possibilities to everyday household items. Whether it's electronic casings, agricultural products, toys or mechanical parts - injection molding effortlessly accomplishes them all. It brings us more diversified and intricately designed products. Like magicians using injection molding techniques to create items of various sizes and shapes that give us an entirely new perspective on the world of plastics.

Stay amazed by how this fascinating process crafts functional aesthetics for transportation and elevates our healthcare experience while adding innovation to everyday items!

Are you intrigued by these captivating and magical injection molding stories? Now you can delve deeper and discover the imprints left by injection molding techniques on the items you use every day. Don't underestimate these seemingly ordinary parts, as they gracefully adorn our lives in the most elegant manner.

It's becoming clear that injection molding is an indispensable technology! Whether it's providing protection for electronic devices, bringing joy to children's playtime, or contributing to advancements in agriculture, it plays a vital role in household necessities, mechanical and automotive components, as well as the healthcare industry.

So now you see, injection molding is both practical and versatile! Whatever product you need, it can be tailored through injection molding. Let us eagerly await the emergence of more marvelous products!

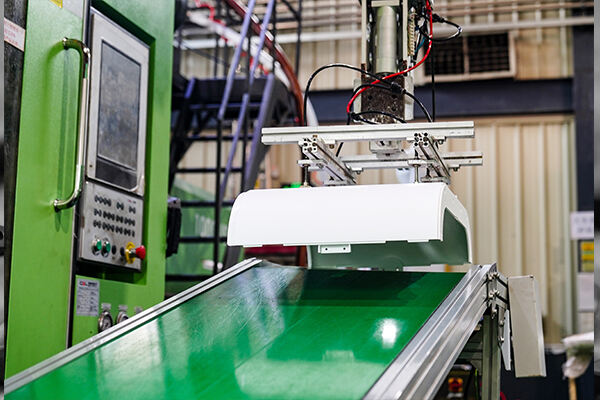

TOPWELL - Your one-stop solution for all your injection molding needs!

Whether it's prototyping or small-batch production, we offer rapid prototyping tools and injection molding services that can meet your needs for 50-5,000 parts.

If you're looking to launch a market campaign, we can create plastic molds for medium-volume injection molding of 5,000-100,000 parts.

And if large-scale mass production is what you require, we also provide production molds to manufacture over 100,000 parts.

For over two decades, we have worked closely with our clients to successfully manufacture various types of injected components.

Join our professional team at TOPWELL today!

ONLINE

ONLINE