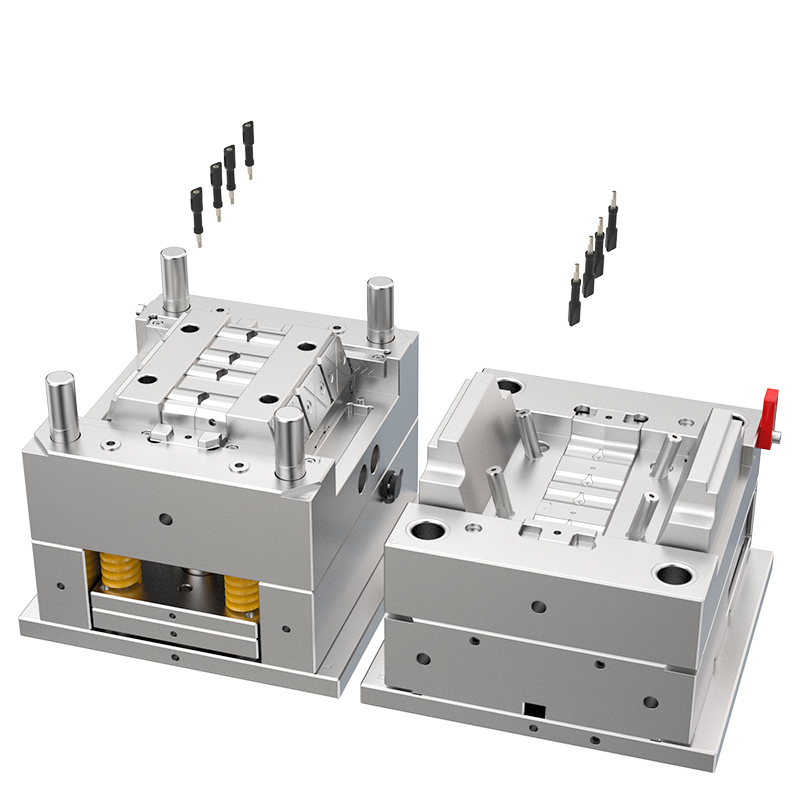

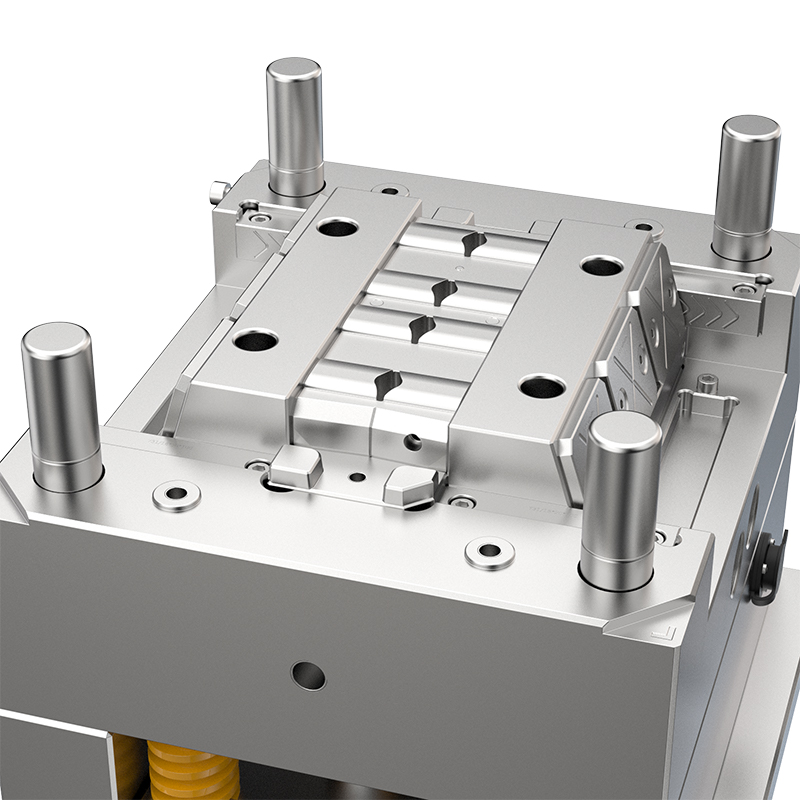

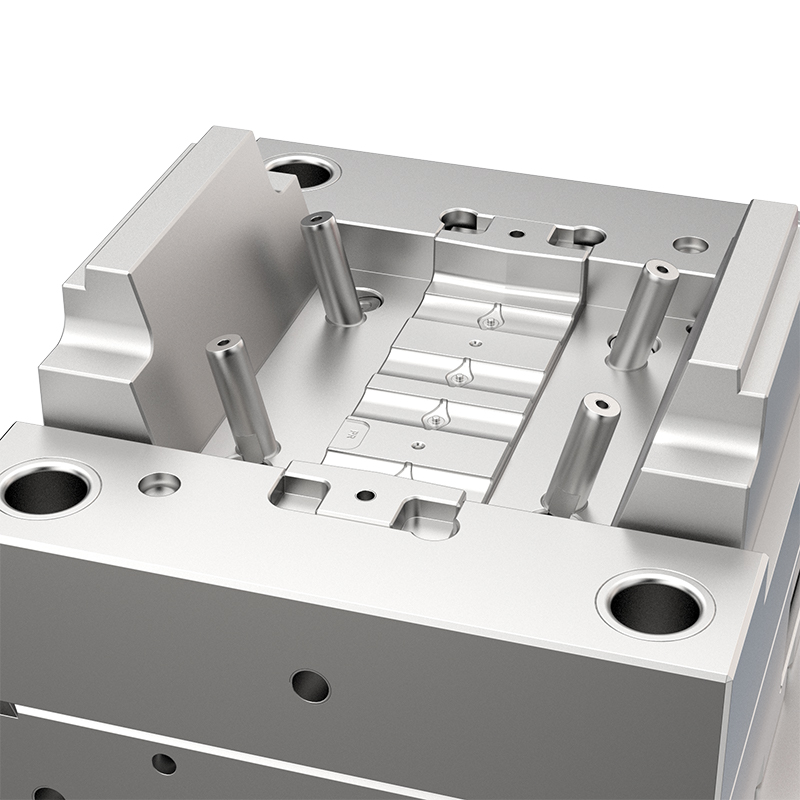

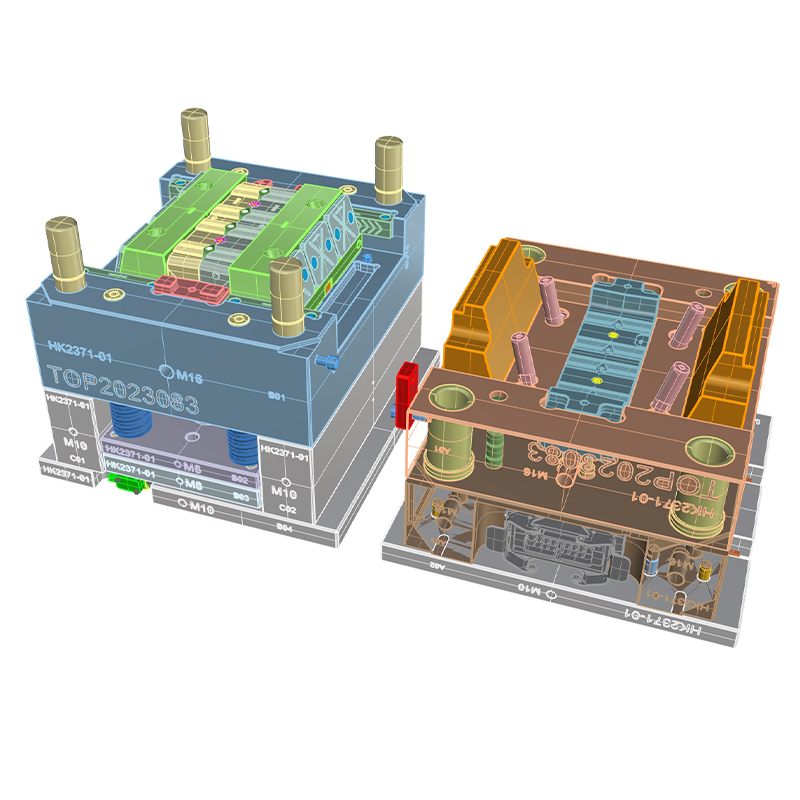

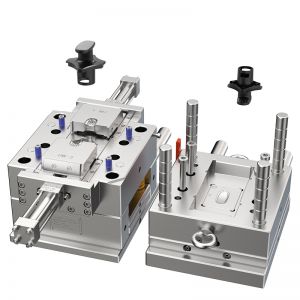

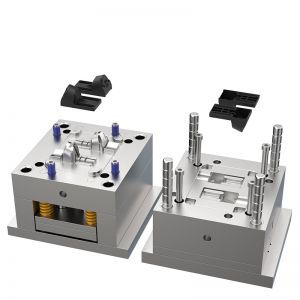

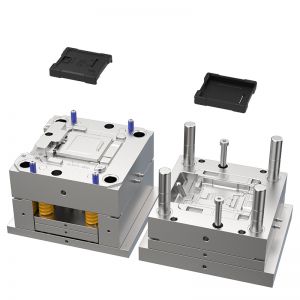

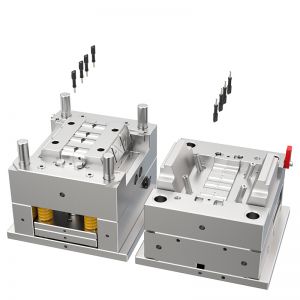

Hardware wrench accessories mold;High-quality wrench mold customization;Durable wrench mold steel;Precision wrench mold production;Expert in injection molding for wrench accessories

Our wrench accessories molds are crafted from top-grade mold steel, boasting exceptional durability and a perfect combination with high-quality injection molding materials. This ensures high precision and durability for the wrench accessories. The mold not only improves production efficiency but also significantly reduces production costs, making it the preferred solution in the hardware accessories industry.

- Overview

- Description

- Details

- Inquiry

- Related Products

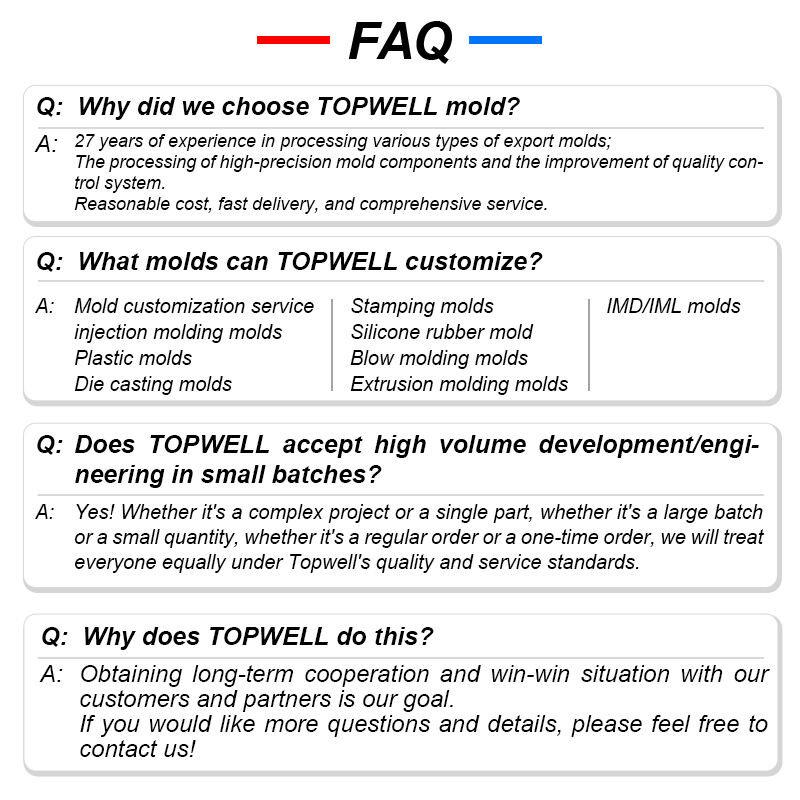

Choose the steel material of the mold according to the characteristics of the plastic

Plastic Material | Mold Request | Mold Life | Material Recommend | Application hardness | Polishing | |||

Corrosion resistance | Wear-resistant | Tensile strength | AISI | YE Brand | ||||

ABS | None | Low | High | Long | P20 | 2311 | 48~50HRC | A3 |

Short | P20+Ni | 2738 | 32~35HRC | B2 | ||||

PVC | High | Low | Low | Long | 420ESR | 2316ESR | 45~48HRC | A3 |

Short | 420ESR | 2083ESR | 30~34HRC | A3 | ||||

HIPS | None | Low | Mid | Long | P20+Ni | 2738 | 38~42HRC | A3 |

Short | P20 | 2311 | 30~34HRC | B2 | ||||

GPPS | None | Low | Mid | Long | P20+Ni | 2738 | 37~40HRC | A3 |

Short | P20 | 2311 | 30~34HRC | B2 | ||||

PP | None | Low | High | Long | P20+Ni | 2738 | 48~50HRC | A3 |

Short | P20+Ni | 2738 | 30~35HRC | B2 | ||||

PC | None | Mid | High | Long | 420ESR | 2083ESR | 48~52HRC | A2 |

Short | P20+Ni | 2738Nitriding | 550~720HV | A3 | ||||

POM | High | Mid | High | Long | 420MESR | 2316ESR | 45~48HRC | A3 |

Short | 420MESR | 2316ESR | 30~35HRC | B2 | ||||

SAN | Mid | Mid | High | Long | 420ESR | 2083ESR | 48~52HRC | A2 |

Short | 420ESR | 2083ESR | 32~35HRC | A3 | ||||

PMMA | Mid | Mid | High | Long | 420ESR | 2083ESR | 48~52HRC | A2 |

Short | 420ESR | 2083ESR | 32~35HRC | A3 | ||||

PA | Mid | Mid | High | Long | 420ESR | 2316ESR | 45~48HRC | A3 |

Short | 420ESR | 2316ESR | 30~34HRC | B2 | ||||

Mold Steel VS Imported Steel

Mold Life | Under 100K | 100K~500K | 500K~1M | Over 1M |

Insert Steel | P20|PX5 738 | NAK80 718H | SKD61(Heat Treatment) TDAC(DH2F) | AIAS420 S136 |

Insert Hardness | (30±2)HRC | (38±2)HRC | (52±)HRC | (60±2)HRC |

Mold Base Steel | S55C | S55C | S55C | S55C |

Mold Base Hardness | (18±2)HRC | (18±2)HRC | (18±2)HRC | (18±2)HRC |

Description

Details

ONLINE

ONLINE