- Overview

- Description

- Details

- Inquiry

- Related Products

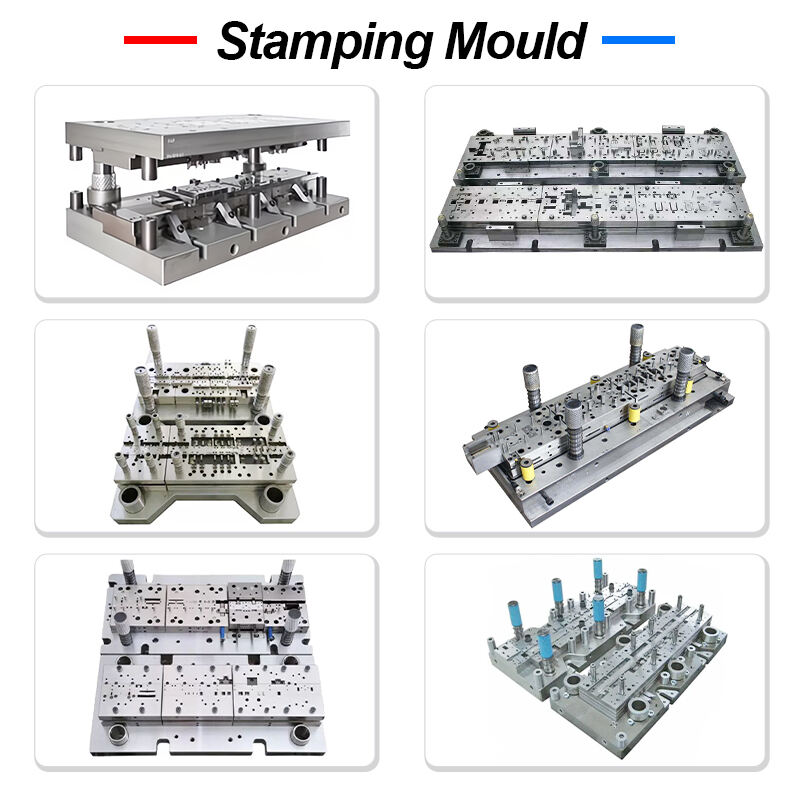

| Products | Metal Stamping Mold |

| High Light | hot runner system metal stamping mold |

| Anodizing metal stamping mold | |

| Anodizing hot stamping mould | |

| Mold Standard | HASCO, DME, Etc. |

| Name | Metal Stamping Mold |

| Material | Metal |

| Mold Base | LKM, HASCO, DME, Etc. |

| Mold Life | 500,000-1,000,000 Shots |

| Application | Automotive, Electronics, Medical, Etc. |

| Surface Treatment | Polishing, Plating, Anodizing, Etc. |

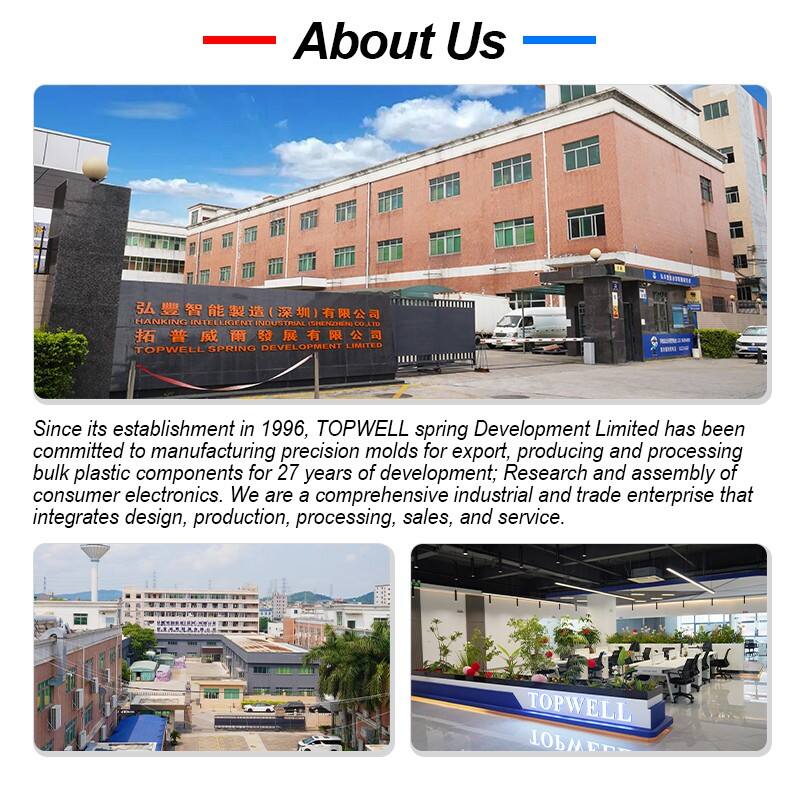

| Place of Origin | China |

| Minimum Order Quantity | 1 set |

Description

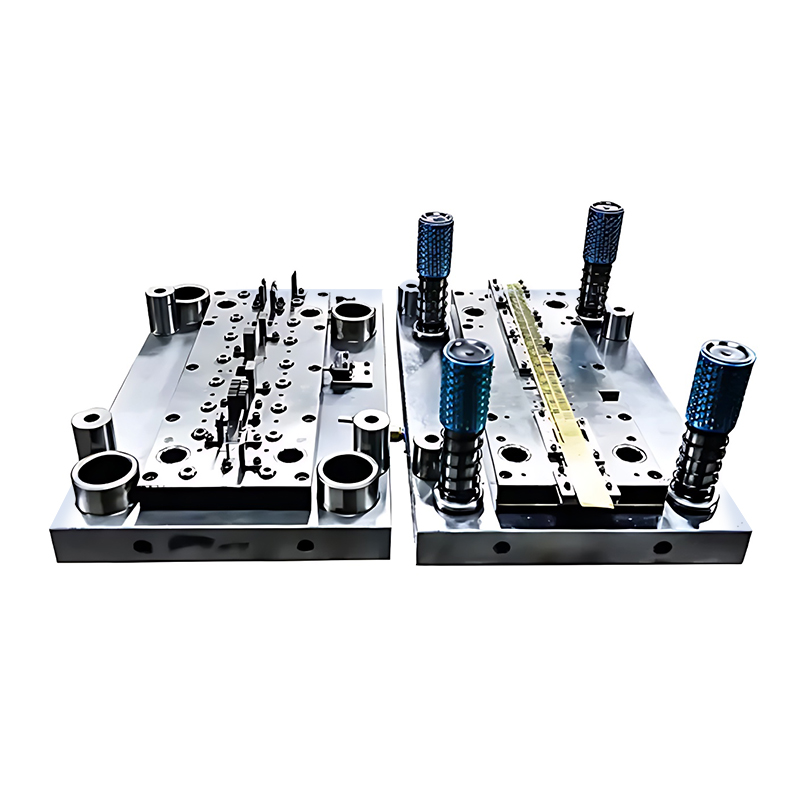

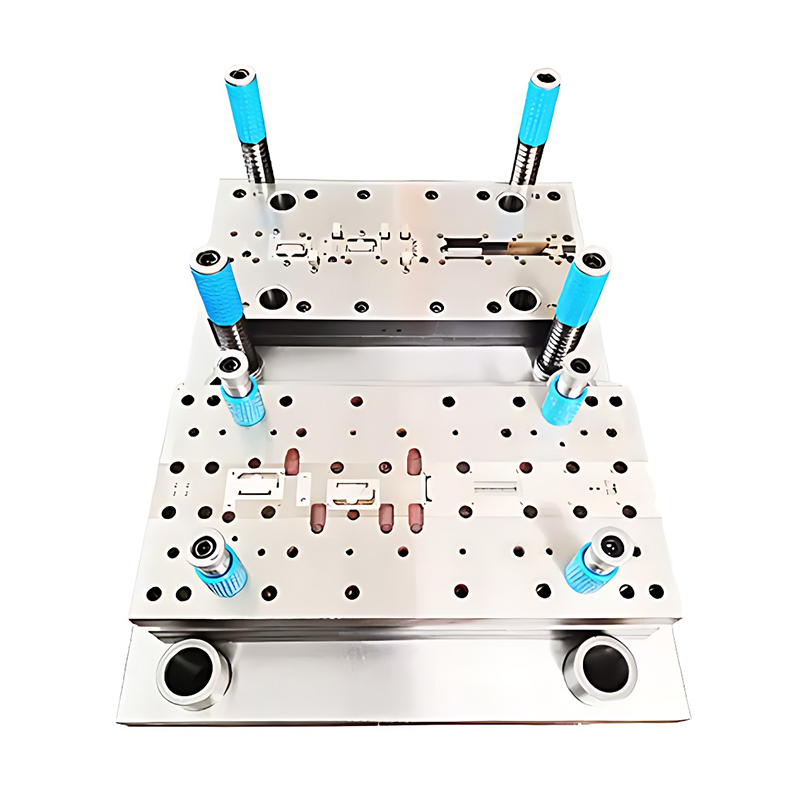

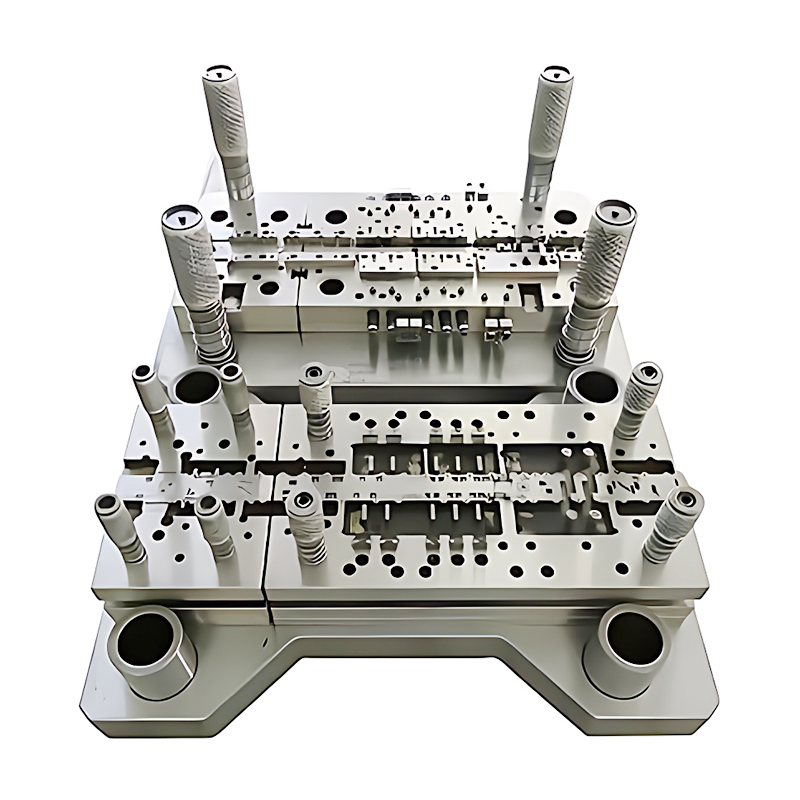

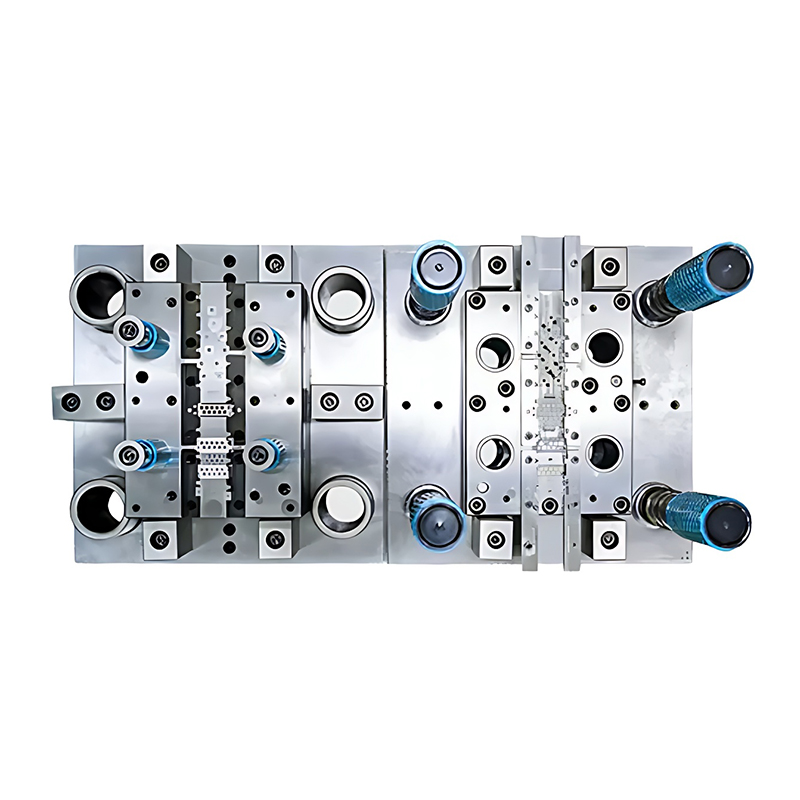

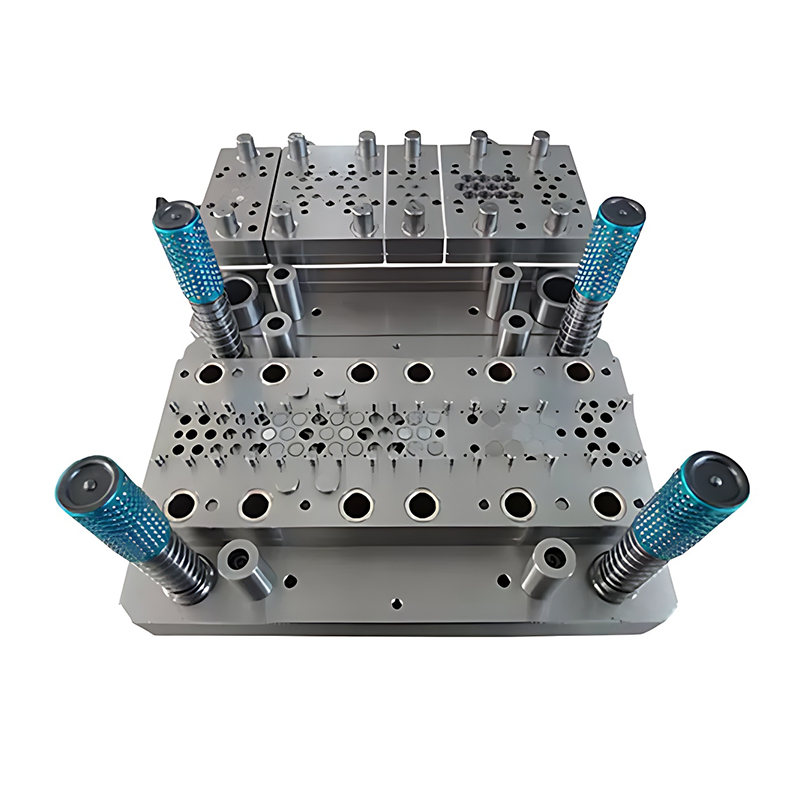

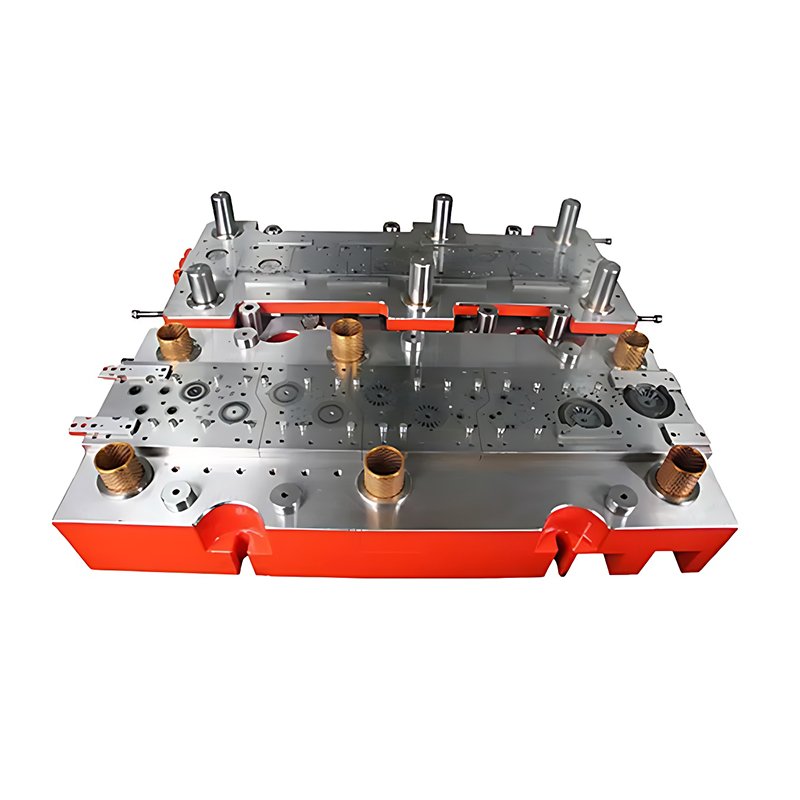

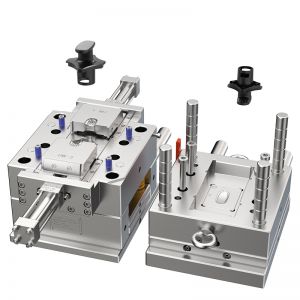

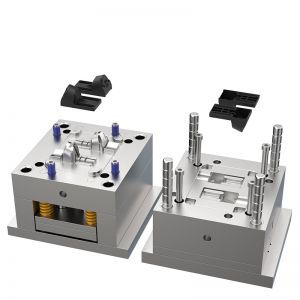

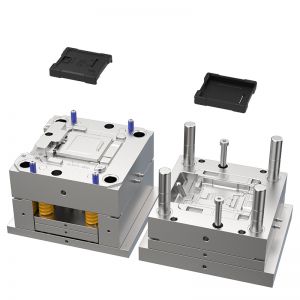

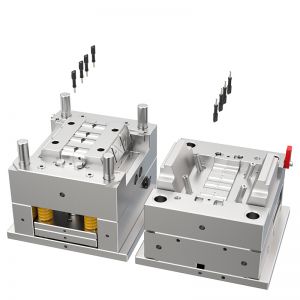

Metal Stamping Mold is a kind of mold used to shape metal materials into desired shapes. It is a versatile tool to produce a variety of metal parts. Its cavity number can be single or multiple, and it is designed with UG, ProE, AutoCAD and other software. It adheres to the HASCO, DME, ISO9001, SGS, RoHS and other standards, and its material is metal. Metal Stamping Mold is a cost-effective and reliable solution for metal part production.

Features:

Product Name: Metal Stamping Mold

Mold Life: 500,000-1,000,000 Shots

Surface Treatment: Polishing, Plating, Anodizing, Etc.

Certification: ISO9001, SGS, RoHS, Etc.

Runner System: Hot/Cold

Mold Base: LKM, HASCO, DME, Etc.

Applications:

Metal Stamping Mold, with its place of origin in China, is an essential tool for any metal stamping product. It has a minimum order quantity of one set and is made of metal, including HASCO, DME, and other mold standards. With a long mold life of 500,000 to 1,000,000 shots, the mold base is also made of LKM, HASCO, DME, and other mold bases, and the runner system can be hot or cold. Moreover, it is equipped with metal stamping die and stamping mold cavity, which are all essential parts for metal stamping products.

Technical Parameters:

| Property | Parameter |

| Surface Treatment | Polishing, Plating, Anodizing, Etc. |

| Tolerance | ±0.01mm |

| Runner System | Hot/Cold |

| Size | Customized |

| Process | Stamping Mold |

| Material | Metal |

| Mold Life | 500,000-1,000,000 Shots |

| Lead Time | 10-15 Days |

| Design Software | UG, ProE, AutoCAD, Etc. |

| Certification | ISO9001, SGS, RoHS, Etc. |

| Stamping Mold Cavity | Customized |

| Metal Stamping Mold | Customized |

| Metal Stamping Die | Customized |

| Metal Stamping Tool | Customized |

Support and Services:

Metal Stamping Mold Technical Support and Service

We provide comprehensive technical support and service for our metal stamping mold products. Our services include:

Assistance selecting the best mold for your project

Expert advice on how to optimize production and minimize costs

Technical support during the design and manufacturing process

Help troubleshooting problems with your existing molds

Repair and maintenance services for your molds

If you have any questions or need help with our metal stamping molds, please don't hesitate to contact us.

FAQ:

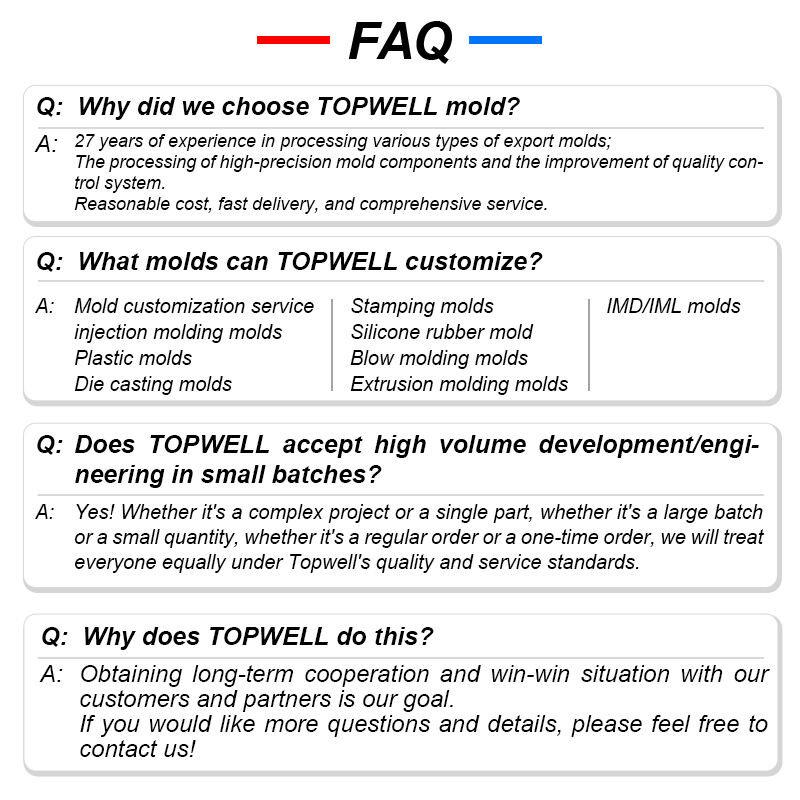

Q1: What is a metal stamping mold?

A1: A metal stamping mold is a tool used to form metal into desired shapes. It is widely used in the metal fabrication industry.

Q2: Where does the metal stamping mold come from?

A2: The metal stamping mold is made in China.

Q3: What is the minimum order quantity for a metal stamping mold?

A3: The minimum order quantity for a metal stamping mold is 1 set.

Q4: What kind of applications can a metal stamping mold be used for?

A4: Metal stamping molds can be used for a wide range of applications, such as forming automotive parts, electronics, medical equipment, and more.

Q5: Is a metal stamping mold durable?

A5: Yes, a metal stamping mold is designed to be durable and withstand the pressure and stress of forming metal parts.

Details

ONLINE

ONLINE