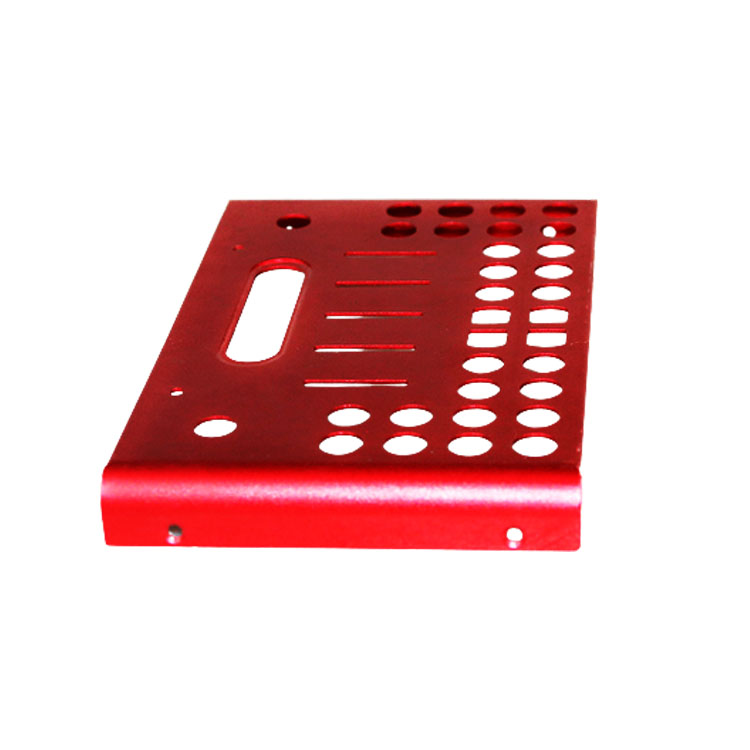

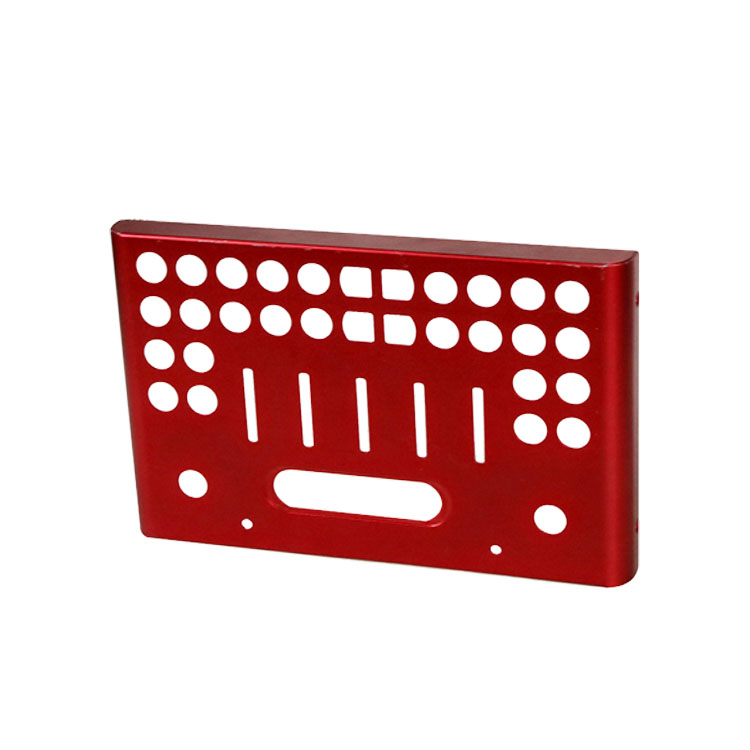

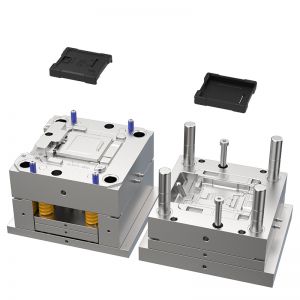

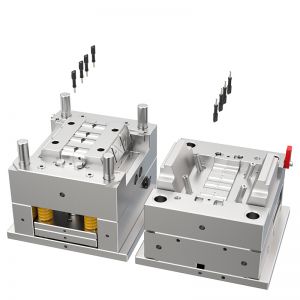

Aluminum Alloy Sheet Metal Press Parts Mobile Spray Oxidation Stamping Machine Parts

Mobile power supply housing Material: Aluminum alloy Surface treatment: spray painting, oxidation and coloring Usage: Electronic devices

- Overview

- Description

- Details

- Inquiry

- Related Products

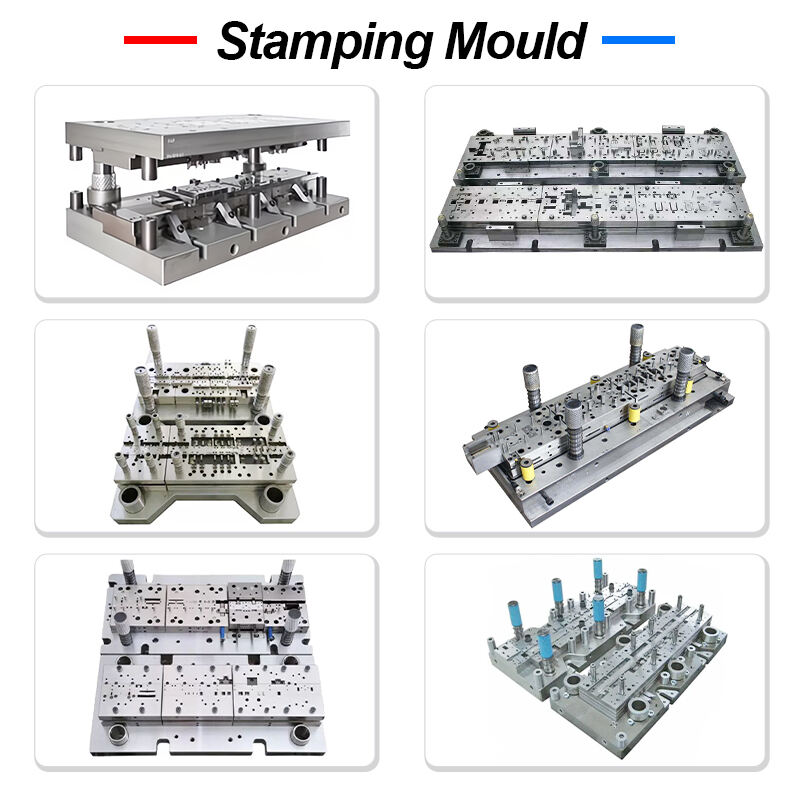

| High Light | Oxidation Sheet Metal Press Parts Spray Sheet Metal Press Parts Aluminum Stamping Machine Parts |

| Material | AL5052 |

| Finished | Sandblasting Anodic Oxidation |

| Color | Silver/red/black/colorful |

| Salt Spray Test | 96 H |

| Tolerance | ISO2768FH |

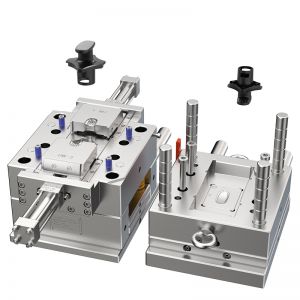

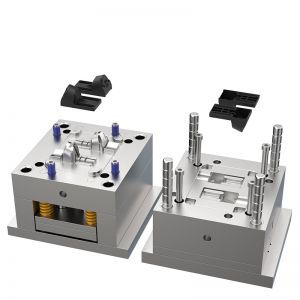

| Process | Cnc Machining, Turning CNC Parts, CNC Milling, Turning, According To The Workpiece And Precision |

| Place of Origin | China Shenzhen |

| Brand Name | TOPWELL |

| Minimum Order Quantity | 100 pcs |

| Price | USD0.5-30 pcs |

| Packaging Details | 32*23*17cm |

| Delivery Time | 5-8 work days |

| Payment Terms | T/T |

| Supply Ability | 10000 pcs days |

Description

Aluminum alloy mobile power supply shell aluminum profile shell powder spray oxidation

Scope

Aluminium alloy 5052 is a medium strength alloy commonly referred to as an architectural alloy.It is normally used in intricate extrusions.It has a good surface finish, high corrosion resistance, is suited to welding and can be easily anodised.Most commonly available as T6 temper, in the T4 condition it has good formability.

Application

This material is used for architectural applications, shop fittings, irrigation tubing, balustrading, window frames,3C cooling parts, Decorative metal panels,mechanical parts, automobile parts, outdoor fitness equipment. extrusions and doors.

Supplied Forms

1 Extrusions

2 Tube

3 sheet material

Alloy Designations

Aluminium alloy 5052-H32 also corresponds to: Al5052-H32, Al Mg0.7Si, GS10, AlMgSi0.5, A-GS, 3.32206, ASTM B210, ASTM B221, ASTM B241(pipe-seamless), ASTM B345 (pipe-seamless), ASTM B361, ASTM B429, ASTM B483, ASTM B491, MIL G-18014, MIL G-18015, MIL P-25995,MIL W-85, QQ A-200/9, SAE J454, UNS A96063 and HE19.

Temper Types

The most common tempers for 5052-H32 aluminium are: O - Soft, T4-Solution heat treated and naturally aged to a substantially stable condition andT6 - Solution heat treated and artificially aged.

Fabrication

A:Solderability: Good

B:Weldability - Gas: Excellent

C:Weldability - Arc: Excellent

D:Weldability - Resistance: Excellent

E:Brazability: Excellent

F:Workability - Cold: Average

G:Machinability: Average

5052-H32 Aluminum Alloy: Properties

| General Characteristics | |

| Characteristic Appraisal | |

| Strength | Medium |

| Corrosion Resistance | Good |

| Weldability & Brazability | Good |

| Workability | Good |

| Machinability | Fair |

| Chemical Composition | ||

| Element Minimum % Maximum % | ||

| Magnesium | 2.22 | 2.8 |

| Silicon | 0.1 | 0.25 |

| Iron | No Min | 0.04 |

| Copper | No Min | 0.1 |

| Manganese | No Min | 0.1 |

| Chromium | No Min | 0.1 |

| Zinc | No Min | 0.1 |

| Titanium | No Min | 0.1 |

| Other Elements | No Min | 0.05 each, 0.15 in total |

| Physical Properties | |||

| Property 5052-H32 | |||

| Density | 2.70 g/cc | 0.0975 lb/in³ | 2.70 g/cc | 0.0975 lb/in³ | 2.70 g/cc | 0.0975 lb/in³ |

| Mechanical Properties | |||

| Property 5052-H32 | |||

| Tensile Strength | 186 MPa | 27000 psi | 241 MPa | 35000 psi | 290 MPa | 42000 psi |

| Yield Strength | 145 MPa | 21000 psi | 214 MPa | 31000 psi | 269 MPa | 39000 psi |

| Modulus of Elasticity | 68.9 GPa | 10000 ksi | 68.9 GPa | 10000 ksi | 69.0 GPa | 10000 ksi |

| Thermal Properties | |||

| Property | 5052-H32 | 5052-H32 | 5052-H32 |

| Coefficient of Thermal Expansion @20.0 - 100 °C Temp | 21.8 µm/m-°C | 12.1µin/in-°F | 21.8 µm/m-°C | 12.1µin/in-°F | 21.8 µm/m-°C | 12.1µin/in-°F |

| Thermal Conductivity | 209 W/m-K | 1450BTU-in/hr-ft²-°F | 200 W/m-K | 1390BTU-in/hr-ft²-°F | 200 W/m-K | 1390BTU-in/hr-ft²-°F |

Details

ONLINE

ONLINE