Shenzhen Topwell Technology Co.,Ltd

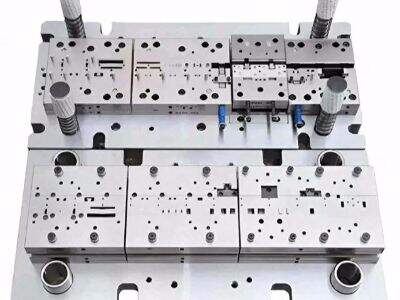

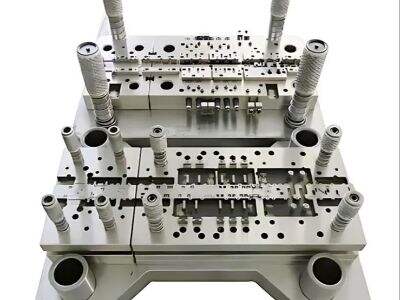

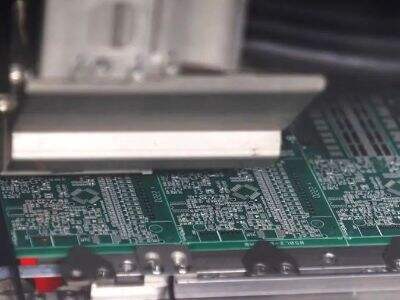

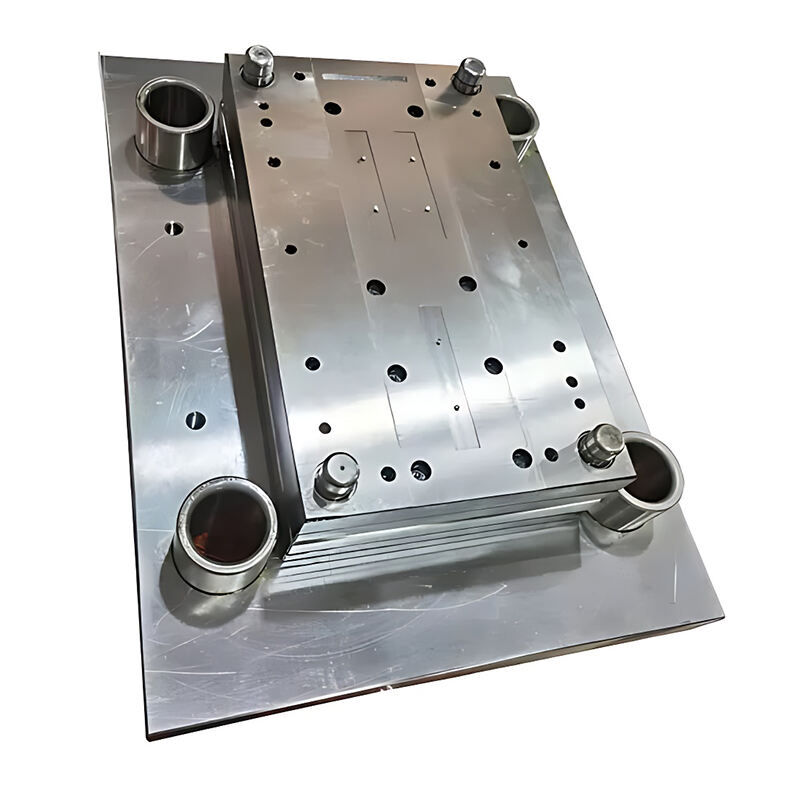

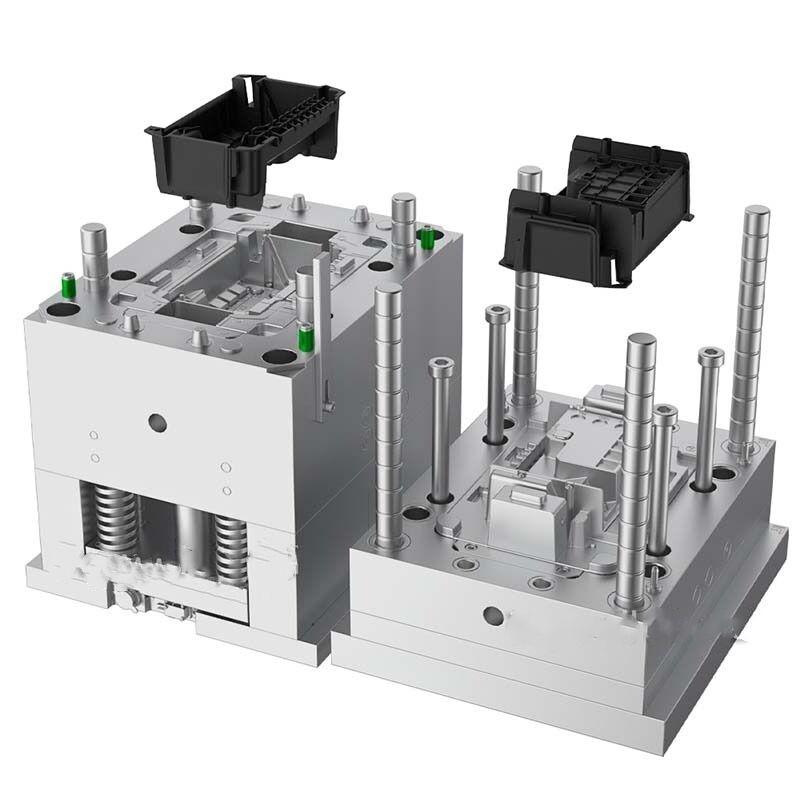

Welcome to Shenzhen Topwell Technology Co.,Ltd, a leading product Manufacturing Company in China with over 27 years of experience. We provide services such as: Industrial Design, Mechanical Design, Mould Design and Manufacturing, Second processing and Product assembly. We also offer one-stop services for plastic parts and products.

EN

EN

ONLINE

ONLINE