Quality and Service of Injection Moulder

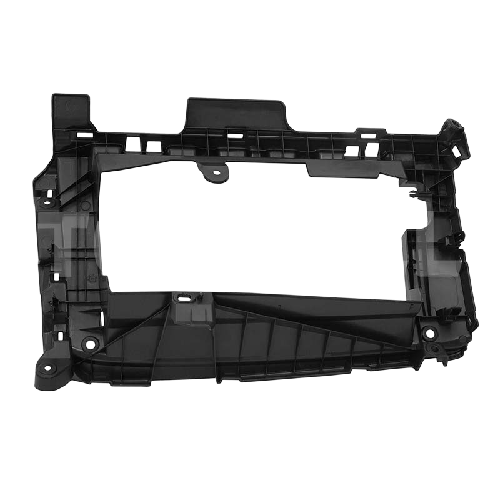

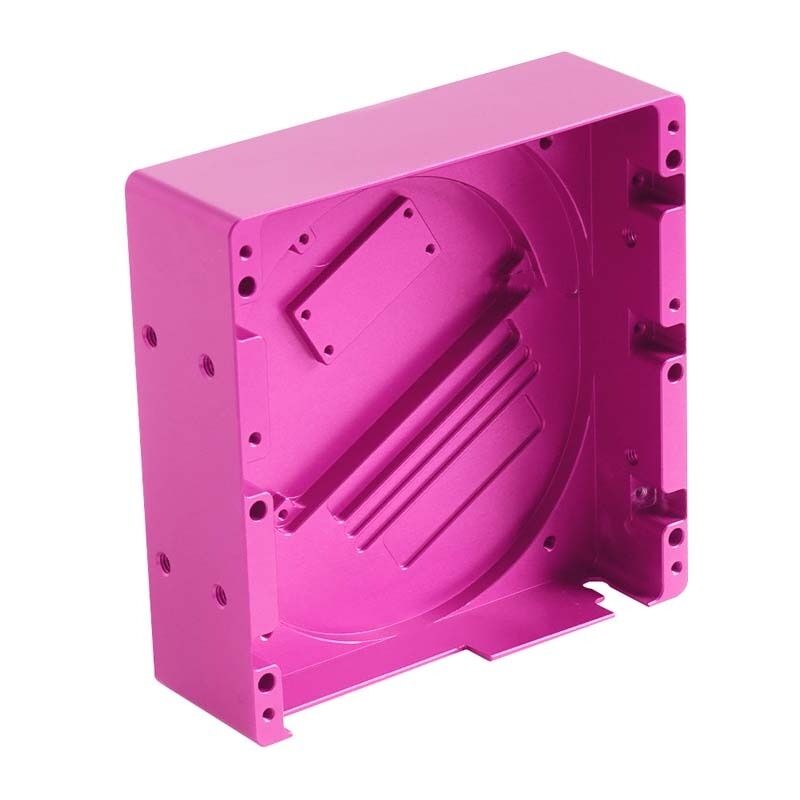

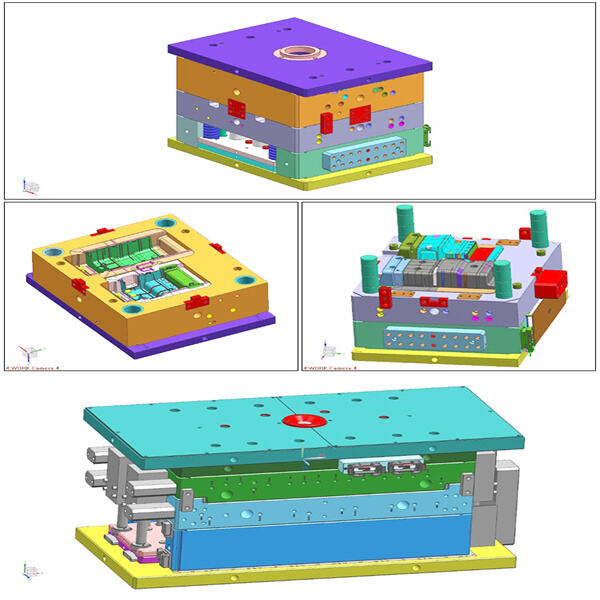

Injection moulding produced products of good quality, by having a area that is consistent. Furthermore, discover why Topwell's product is the go-to choice for professionals worldwide, specifically plastic injection mold. The conventional of an item this is certainly injection-moulded inarguably high. Along with this, injection moulders are really simple to use, easy maintenance procedures, and extremely durable when efficiently used. They just need minimal maintenance procedures, as well as can work on a basis this is certainly 24-hour.

The clear answer that is after-sales an element that is important account for when purchasing an injection moulding machine. The maker and provider should offer consumer that is great and support, help with installation, and gives operator and training that is upkeep. Regarding the repair and upkeep solution, the manufacturers should answer the consumer's inquiries quickly and gives repair this is certainly effective upkeep services.

EN

EN

ONLINE

ONLINE