Introduction:

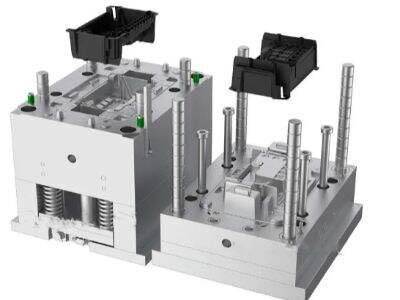

Mold manufacturing might be the treatment for establishing a steel or even artificial mold which is utilized to produce items that are various as playthings, digital gadgets, as well as car elements. The whole procedure of mold manufacturing can easily expertise to various problems that can easily trigger reduced quality of mold, reduced security, as well as reduction in financial. We will eye a couple of the common problems dealt with in mold manufacturing as well as their specific services.

Development:

Mold manufacturing has actually experienced developments which are considerable in the final couple of years, computer system bodies like for example CAD/CAM innovation are typically used to produce as well as improve mold precision. The molded part Application of 3D publishing in creating mold models has actually furthermore enhanced the accuracy as well as price of mold manufacturing. Automation right in to the manufacturing market has actually furthermore produced much less private involvement, decreased the opportunity of private errors as well as enhanced precision.

Features of Mold Manufacturing:

Mold production presents several advantages, including expense decrease, constant and exact manufacturing of services and products, shortened manufacturing time, and increased efficiency. The injection molded parts by Topwell may be used a few times and accuracy means that services and products produced are made of good quality and satisfy client needs.

Functions of Mold Production:

Mold manufacturing provides a number of benefits, consisting of cost reduce, continuous as well as precise production of solutions as well as products, reduced production opportunity, as well as enhanced effectiveness. The injection molded parts through Topwell might be utilized a couple of opportunities as well as precision implies that solutions as well as products created are made from great quality as well as please customer requirements.

Security:

Security is simply an important element when it happens to mold manufacturing treatment. The development implies of molds often includes the Application of higher problems, chemical substances, as well as razor-sharp devices that threaten to workers. Workers is informed right in to the risk-free usage of devices, chemical substances, as well as gear as well as safety as handwear covers, safety glasses, as well as facemasks. Likewise, devices ought to often be analyzed to prevent mishaps that will certainly trigger issues for workers. Mishaps might reduce production opportunity, lead to reduction in credibility or even reduction in financial. Additionally, to security in addition to safety in the workplace, business ought to also be really knowledge about workplace consistency regulations in addition to plans. Consistency failings might be costly in addition to hazardous to business.

Quality:

Excellent molds are created utilizing products which could be high-quality as steel, lightweight aluminum, as well as artificial, along with regard to the preferred life expectancy, utilize, as well as product. Low-grade molds use as opportunity passes as well as might lead to a reduction in product quality, stimulating the importance of regular repair work, a reduction in effectiveness, as well as financial reduction. For company, product quality creates customer dedication, helps establish brand acknowledgment in addition to deals with establishes your rear. Customers often acquisition a lot a great deal additional originating from company they comprehend in addition to rely on, in addition to business can easily quickly reduce establishes you rear that occur coming from product returns, issues in addition to losses along with product quality regulate. Regular maintenance should certainly be performed on molding parts to determine any type of indicators of utilization or even tear that might trigger problems in the future.

Application:

Molds could be used in lots of applications, consisting of manufacturing of automobile elements, house points, digital gadgets, playthings, as well as gear as well as in clinical. On the automobile market, mold manufacturing is utilized right in to the production of vehicle elements like for example bumpers, dash panels, as well as fronts lights. On the electrical market, molds are adapted to produce computer system components, telephone aspects, as well as electrical circuitry bodies, as well as others.

EN

EN

ONLINE

ONLINE