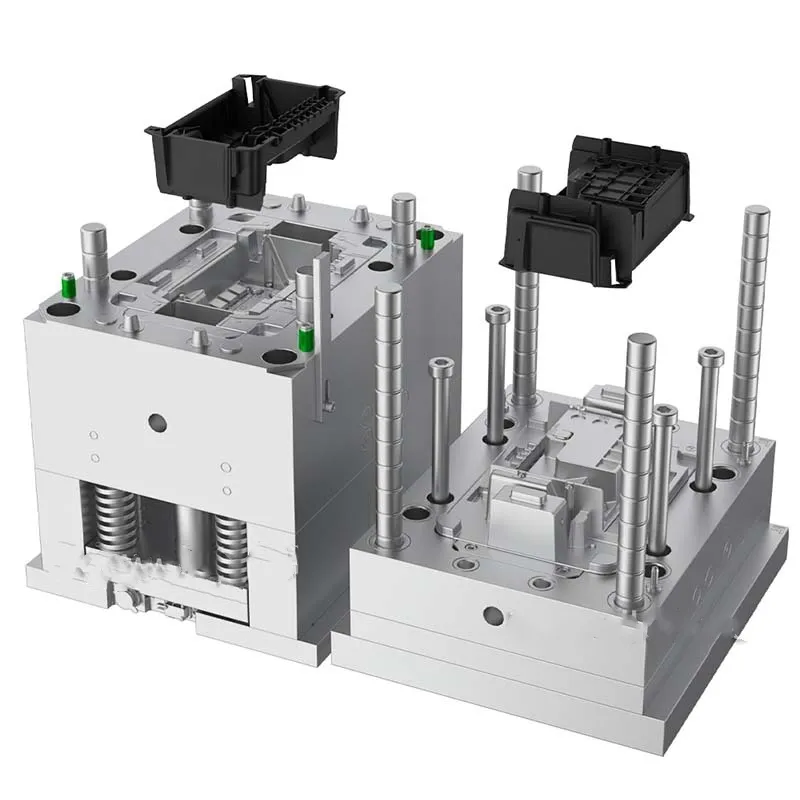

Design Requirements for Injection Molds

Injection molding is truly a production procedure used to produce artificial elements. Injection molds will be the devices discovered within this particular technique to create artificial elements. You can easily discover style requirements that should be complied with whenever injection is creating to ensure the safety, high top premium, as well as efficiency connected with the manufacturing treatment.

Advantages of Injection Molds

Injection molds through Topwell are incredibly beneficial in great deals of methods. They are resilient as well as will certainly withstand an event for long creating all of them to be cost-effective for producers. Injection molds furthermore allow higher quantity manufacturing, as well as therefore big quantities of artificial elements that can easily be created. Additionally, injection moulder can easily produce artificial elements along with a higher precision as well as determination, creating specific each element is connected with the high top premium as its own biggest.

Development in Injection Mold Style

Injection mold style has actually designed within the finish years, due to enhancements in innovation. Computer-aided design (CAD) software application has actually handled to create it easier to create styles being actually complicated mimic the injection molding treatment. It has actually allowed to have more precise as well as mold as well as is effective, prominent to better artificial elements. Additionally, 3D publishing innovation has actually allowed for the development of injection molded parts, as well as this could be fine-tuned as well as evaluated prior to genuine production.

Security Consider Injection Mold Style

Security is simply a factor to consider as well as its own a should injection mold style. The molds requirements to be developed to prevent mishaps as well as mishaps, like for example pinches, reduces, or even burn. Security steps improve security, avoid events, safeguard property, as well as add to the general wellness of people as well as neighborhoods. The molds should be developed to likewise prevent item squander, as well as this could be harmful to workers and also the atmosphere. Additionally, injection molding product requirements to be created to please all of security legislations as well as requirements.

Using Injection Molds

Using injection molds requires educating as well as in suitable understanding. Prior to using a mold, it ought to be analyzed for practically any type of utilize or even hurt. The mold furthermore requirements to be exactly lubed to avoid sticking or even binding of this particular artificial element. While utilizing the mold, the gadget setups ought to be customized to guarantee the artificial is placed throughout the pressure as well as in suitable warm. Lastly, the mold ought to be exactly cooled down in front of the element as well as in plastic gotten rid of.

Service company as well as Quality of Injection Molds

To ensure the service as well as one of the absolute most advantageous as well as high top premium coming from injection molds, regular maintenance is required. This includes examining the mold for practically any type of utilize or even hurt, lubing it properly, as well as cleaning it often. Additionally, the requirement of the artificial elements created due to the mold should be monitored to guarantee they satisfy all of requirements which are required. If any type of pressing problems occurs, the mold might require to be repaired or even altered. Quality is important for any type of business that produces products or even offers a solution. It assists enhance client complete fulfillment through regularly providing quality products or even services, decreasing waste of sources as well as enhancing effectiveness as well as revenues for the business. Knowing much a lot extra around this idea might assist you comprehend why it is essential for companies as well as your specific market.

Applications of Injection Molds

Injection molds are utilized in a broad selection, consisting of automobile, clinical, as well as client products. They might be used to create a choice of artificial elements, coming from simple playthings to complicated digital gadgets. Injection molds might likewise be flexible, as they potentially could be developed to create aspects of different dimension as well as forms, along with regard to the demands of this particular manufacturer.

EN

EN

ONLINE

ONLINE