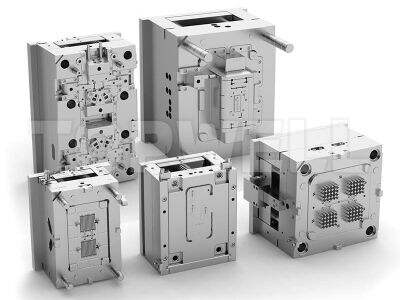

Top 10 Injection Molding Companies in the World

Injection molding is a procedure involves items are producing components by infusing melted products into a mold and mildew. The process has transformed the manufacturing industry by production it feasible to produce forms are complex designs with high degrees of accuracy. Here are the top 10 Topwell injection molding companies on the planet.

Advantages of Injection Molding

Injection molding has several benefits of manufacturing processes. Among them the capability to forms are manufacture are complex high degrees of accuracy. The process uses a range wide, consisting of plastics, steels, and porcelains. Injection Molding Companies enables the development of get rid of consistent quality, reducing the need for post-production work.

Innovation in Injection Molding

Injection molding companies are innovating to improve their processes and produce better items. One development such the use additive manufacturing, which enables the development of complex get rid of elaborate designs. Another development the use simulation software to optimize designs and decrease the risk of mistakes.

Safety in Injection Molding

Safety an issue injection molding critical. Companies must ensure their processes are safe for employees and the products they use don't position health and wellness dangers. Precaution consist of the use safety equipment, proper air flow, and the educating of employees on safe methods.

Use Injection Molding

Injection molding used to produce a range wide of, from clinical devices to components are automobile to home items. The process ideal for production items with complex forms, precise measurements, and quantities are high. Injection Molding affordable for high-volume manufacturing runs.

How to Use Injection Molding?

Injection molding involves several actions, consisting of mold and mildew design, material choice, and injection. The process starts with the development of the mold and mildew, which designed to the precise specs of the item. The mold and mildew after full of melted products, which are infused under high stress into the mold and mildew cavity. The products are after enabled to cool and solidify before the mold and mildew opened up, and the item finished removed.

Service and Quality in Injection Molding

When choosing an injection moulder company, it is essential to think about their solution and quality. The very best companies offer a range filled with, from design and design to item testing and optimization. They should have quality measures are stringent place to ensure their items satisfy or exceed industry requirements. Looking for companies with accreditations such as ISO 9001 or TS16949, which are recognized worldwide for quality management.

Application of Injection Molding

Injection molding used throughout a range wide of and applications, from aerospace to customer items. Some instances of items produced through injection molding consist of clinical equipment, automobile components, and devices are digital. Shot molding used in the manufacturing of playthings, home items, and product packaging products.

EN

EN

ONLINE

ONLINE